Hard Shell - Soft Core

Polymeric microspheres have a shell whose density is dependent on the temperature

nanoparticles whose outer shells and inner cores are made of different materials are useful for many industrial and biomedical applications. In order for nanoparticles to be used as sensors or for the controlled release of substances held within their shell, for example, an important requirement must be met: the shell must be more dense than the core to form a barrier for the external medium.

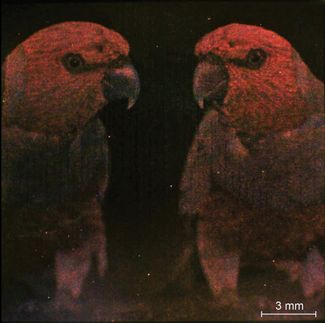

W. Richtering and I. Berndt in Aachen, in collaboration with J.S. Pedersen in Århus, Denmark, have now found an elegant solution to this problem. In a two-step process, they synthesized polymeric microspheres with a core made of poly-N-isopropylacrylamide and a shell of poly-N-isopropylmethacrylamide. Both polymers are known for a particular characteristic: they swell in water, forming microgels. Because of the different polymer building blocks used in the shell and core, these differ in the absorption of water.

At 70°C, the temperature at which the microspheres are synthesized, both polymers are densely packed. They cannot take up much water and thus no substances dissolved in the water either. When they are cooled to 25°C, the core and shell have the highest water content and the lowest density. Dissolved molecules can pass through the shell into the core, where they disperse. Things get especially interesting when the temperature is raised to 39 °C: at this temperature, only the swelling properties of the shell are changed. It expels water, shrinks together, and becomes denser than the core. Substances dissolved in the core can no longer pass through the shell and are now locked inside.

Aside from their sensitivity to temperature, polymeric microgels with core-shell architectures have another advantage too. Selection of the basic components and the reaction conditions also allow other properties of the polymers to be controlled. In addition, the synthesis of particles with multiple shells is also a possibility; these could separate different reaction chambers within the particle. The possible applications are many and varied.

Original publication: W. Richtering et al.; "Temperature-Sensitive Core-Shell Microgel Particles with Dense Shell"; Angewandte Chemie International Edition 2006, 45, 1737.

Most read news

Topics

Organizations

Other news from the department science

These products might interest you

Eclipse by Wyatt Technology

FFF-MALS system for separation and characterization of macromolecules and nanoparticles

The latest and most innovative FFF system designed for highest usability, robustness and data quality

Spinsolve Benchtop NMR by Magritek

Spinsolve Benchtop NMR

Spinsolve is a revolutionary multinuclear NMR spectrometer that provides the best performance

HYPERION II by Bruker

FT-IR and IR laser imaging (QCL) microscope for research and development

Analyze macroscopic samples with microscopic resolution (5 µm) in seconds

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

See the theme worlds for related content

Topic world Synthesis

Chemical synthesis is at the heart of modern chemistry and enables the targeted production of molecules with specific properties. By combining starting materials in defined reaction conditions, chemists can create a wide range of compounds, from simple molecules to complex active ingredients.

Topic world Synthesis

Chemical synthesis is at the heart of modern chemistry and enables the targeted production of molecules with specific properties. By combining starting materials in defined reaction conditions, chemists can create a wide range of compounds, from simple molecules to complex active ingredients.

Topic world Sensor technology

Sensor technology has revolutionized the chemical industry by providing accurate, timely and reliable data across a wide range of processes. From monitoring critical parameters in production lines to early detection of potential malfunctions or hazards, sensors are the silent sentinels that ensure quality, efficiency and safety.

Topic world Sensor technology

Sensor technology has revolutionized the chemical industry by providing accurate, timely and reliable data across a wide range of processes. From monitoring critical parameters in production lines to early detection of potential malfunctions or hazards, sensors are the silent sentinels that ensure quality, efficiency and safety.