Dow Dispersion Sciences Brings Novel Solutions to the Personal Care Industry

The Dow Chemical Company has launched Dow Dispersion Sciences (DDS), a new business dedicated to pioneering advancements in emulsions and dispersions technology that benefit the personal care industry. Through expertise in emulsion and related technologies, DDS provides novel solutions that enhance product functionality, improve operational efficiency, and shorten the time it takes for personal care companies to create and market innovative new products. The introduction of Dow Dispersion Sciences broadens Dow's already strong portfolio of personal care businesses, which includes Amerchol Corporation, a subsidiary that manufactures and markets performance chemicals globally; and Dow Biocides, which offers antimicrobial chemistries for consumer and industrial applications.

"Dow Dispersion Sciences accelerates innovation by improving the process by which currently available raw materials are incorporated into personal care formulations," explains Dave Hatfield, business director, Dow Dispersion Sciences. "This improves the functionality of personal care formulations by either allowing the use of raw materials that were difficult to use in the past, or by significantly improving the performance of currently used raw materials."

Key Benefits Dow Dispersion Sciences offers customers three key benefits - improved functionality, reduced costs, and faster time to market. According to Hatfield, "These benefits appeal to multiple functions in personal care companies, especially marketing, technology and production. Added together, they equal significant competitive advantage, and customers have been responding very well to our offering."

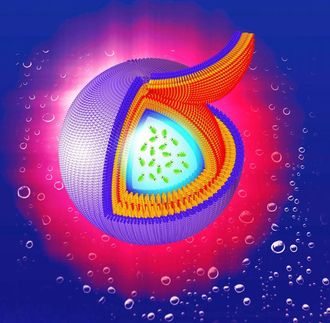

About the Technology and Products The first commercialized technology in the DDS portfolio is a proprietary mechanical dispersion technology. When combined with Dow's formulation, process and interfacial science expertise, it enables the production of highly concentrated oil-in-water emulsions (75-95% oil), with tightly controlled particle size (<1 micron) and minimal surfactant. The resulting emulsion concentrate is easily dispersed in a customer's formulation, with low shear and ambient temperature. Particle size is tailored to enhance stability, texture and functionality. The process is not dependent on high temperature or high shear, allowing for handling of materials which are heat sensitive (actives, botanicals, etc.), shear sensitive or highly viscous [up to 500,000 centipoise (cp)].

Sarah Eckersley, Research & Development leader for DDS says, "While there are a number of emulsion processes available to the industry, our proprietary technology provides a unique combination of benefits that no other single process can duplicate. This allows us to tailor novel solutions to meet the specific needs of individual customers and the industry. For example, with our technology, we can dramatically enhance the efficacy of UV absorbers in formulated suncare and daily wear products. This exciting development, combined with our ability to enhance formulation stability and aesthetics, allows a formulator to develop high performance products, faster and more cost effectively than ever before."

Three Offerings DDS technology is offered in three forms: raw material concentrates (emulsion concentrate of a single oil-phase ingredient), custom pre-blends (emulsion concentrate of multiple oil-phase ingredients) and finished product formulations that are difficult to manufacture via traditional processes.

Introductory Focus The initial focus of DDS is on the skincare and suncare markets, where its technology has been successfully applied to a broad range of ingredients including triglycerides, petrolatum, silicone elastomers, waxes and UV absorbers. The initial target geographies include North America and Europe, followed by Asia Pacific and Latin America.

Other news from the department business & finance

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.