Copper shock: An atomic-scale stress test

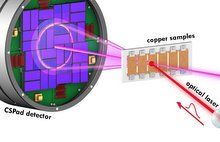

Scientists used the powerful X-ray laser at the U.S. Department of Energy's SLAC National Accelerator Laboratory to create movies detailing trillionths-of-a-second changes in the arrangement of copper atoms after an extreme shock. Movies like these will help researchers create new kinds of materials and test the strength of existing ones.

Greg Stewart/SLAC

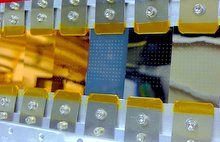

D. Milathianaki, S. Boutet, et al.

D. Milathianaki, S. Boutet, et al.

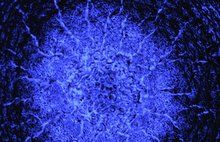

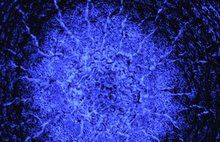

Microscope image of resolidification patterns formed on the surface of silicon after the passage of a shock wave. Scientists at LCLS applied optical laser pulses to launch shocks on various materials on a silicon surface, inducing rapid changes in their lattice. The changes unfolding at rates of trillionths of a second apart were unveiled using the ultrabright free electron laser of LCLS.

D. Milathianaki, S. Boutet, et al.

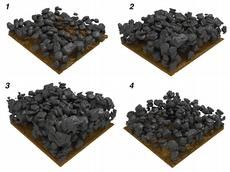

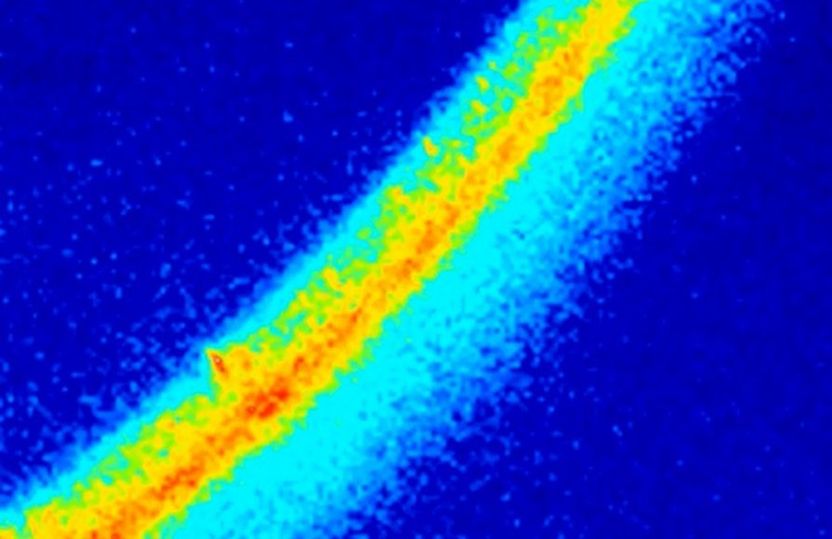

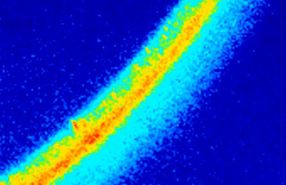

One of a sequence of images showing how a laser-driven shock impacts the crystalline structure, or lattice, of a thin copper sample. The images were combined into a movie that shows trillionths-of-a-second changes in the lattice.

D. Milathianaki, S. Boutet

This work pinpointed the precise breaking point when the extreme pressures began to permanently deform the copper structure, or lattice, so it could no longer bounce back to its original shape. Such experiments provide a direct test of complex computer simulations that model the behavior of many millions of atoms within tiny samples of material.

Such simulations are used to design stronger, more durable materials – such as shielding for satellites to withstand high-speed pelting by space debris – but they have been hard to test in the lab because of the tiny samples and short timescales involved.

"The results enable a number of materials experiments that can be compared to simulations at the same scales," said Despina Milathianaki, a staff scientist at SLAC's Linac Coherent Light Source (LCLS) who led the experiment. "This and future experiments, designed to provide a direct comparison with simulations, will help us to accurately predict the strength of materials in extreme conditions."

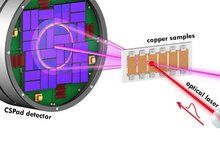

In this experiment, researchers shocked a layer of copper about 1 thousandth of a millimeter, or 1 micron thick with optical laser pulses, and then probed the copper’s lattice with ultrabright X-ray pulses. They compiled the X-ray images into atomic-scale movies that detail how the lattice responded at various times after the shock, including the moment the copper reached its breaking point.

"The demand for research time at LCLS is already at a premium, and these results demonstrate yet another new technique that we believe will open the door to a host of new experiments," said Sebastien Boutet, who leads LCLS's Coherent X-ray Imaging (CXI) Department, where the measurements were performed.

The same research team – composed mostly of SLAC scientists, with collaborators from University of Oxford, Stanford University and Lawrence Livermore National Laboratory – also shocked other metals, including iron and titanium, and is analyzing the data obtained from those samples.

Follow-up research scheduled at LCLS in March seeks to extend the research to additional materials and to enlist other x-ray scattering techniques, which may provide more details about the origins of the damage in the lattice.