Researchers love triangles

Shaped catalysts spark longer, faster-growing, rule-breaking nanowires

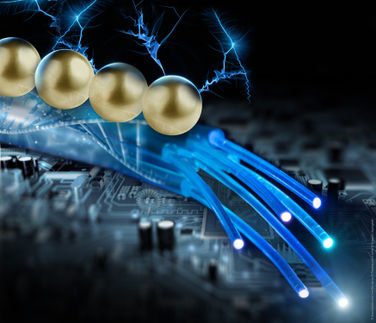

A research team at Case Western Reserve University has found that gold catalysts shaped in the form of a cube, triangle, or other higher order structures grow nanowires about twice as fast and twice as long compared to wires grown with the more typical spherically-shaped catalysts.

This finding could prove useful to other scientists who are growing nanowires to build sensors fast enough to detect changes in red and white blood cells. These sensors in turn could help identify various forms of cancer in the body. The wires are so small – as small as one-5,000th the width of a human hair - they could also be used to build the next generation of "invisible" computer chips.

Xuan Gao, assistant professor of physics, and R. Mohan Sankaran, associate professor of chemical engineering, describe their work in the paper, "Shape-Controlled Au Particles for InAs Nanowire Growth," published in the journal Nano Letters.

Their research team included Case Western Reserve graduate students Pin Ann Lin and Dong Liang and Hathaway Brown Upper School student Samantha Reeves.

The researchers tested growth using both the preferentially-shaped and spherical catalysts under identical conditions to rule out error in the comparisons.

They suggest that the long accepted model of vapor-liquid-solid, or VLS, growth is incomplete, and that more tests are needed in order to fully understand the process.

Here's why: the researchers found that that the nanowires grown with the triangular catalyst have a much thicker layer of the metal Indium than the VLS nanowire growth model predicts.

The finding suggests a correlation between Indium concentration and growth enhancement. The team made the discovery when they beamed electrons at the nanowires to release high energy x-rays, a process called energy-dispersive X-ray spectroscopy. The magnitude of these energy bursts were used to determine chemical properties of the nanowires.

To grow nanowires, the researchers combined elements such as indium and arsenic, from rows 4 and 5 of the periodic table of elements. Elements from these rows bond to the gold particle to create a semiconductor that neither allows great flow of electric current nor greatly prevents its flow. This is called the "bottom-up method" which Gao describes as truly like "growing a plant from a seed."

Nanowires can also be made "top-down" with precise cuts on a large piece of semiconducting material, reducing it to a tiny structure of wires.

The disadvantage to this, Sankaran explains, is that cutting wires smaller than around 45 nm, which is the current standard in computer chips, "is impossible if we are using a machine. But if we were to grow the wires from chemical compounds we could make them as small as 10 nm, meaning we could fit more wires in a smaller space for greater speed."

However the bottom-up method only produces wires in bunches as opposed to the large interwoven structures made from the top-down method of cutting. The challenge is combining chemically-grown wires in ways that they work in complex electronics such as computer chips or highly-sensitive sensors.

Both Gao and Sankaran describe their research efforts as truly collaborative. Sankaran makes catalysts of different shapes to grow the nanowires, and Gao tests the properties of these wires and connects them to possible uses in the field.

This duo plans to continue exploring the correlation between catalyst shape and other structural characteristics of the wires in order to further develop the VLS model, and move closer to implementing nanowires in new technology.

Most read news

Other news from the department science

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.