Micronit develops microreactor module for use in industrial production

Micronit Microfluidics has developed a microreactor module that enables fine chemical companies to perform fluid reactions on an industrial scale in a continuous process. The module is currently been evaluated by DSM Pharmaceutical Products.

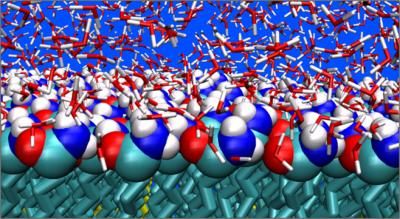

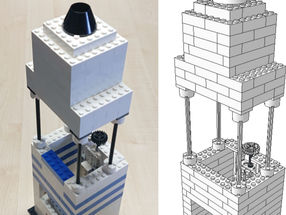

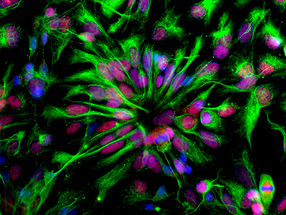

The microreactor is a monolithic glass module of 10 stacked reaction channels with a joint internal volume of 100 millilitres. In the module, a wide range of functionalities have been integrated that enable chemists to mix fluids, let them react, and stop a reaction after a certain time. The temperature of the reaction is actively cooled by means of integrated cooling channels.

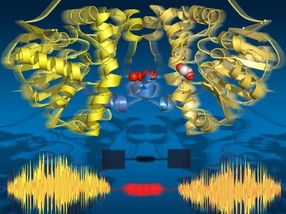

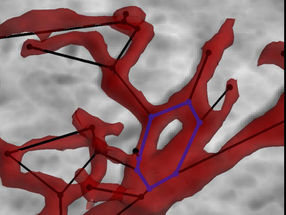

Microreactor technology turns fluid reactions that have always been performed in small batches into continuous processes. The switch from batch to continuous flow results in safer and more efficient chemical production. Furthermore, the continuous flow reactors can easily be scaled to obtain extra production capacity for a particular reaction.

“Microreactor technology has been identified by DSM Pharmaceutical Products as a promising way of process intensification, significantly improving the sustainability of some production processes”, explains Raf Reintjens, Competence manager Process Intensification with DSM Pharmaceutical Products. “The road to industrial applications requires a close collaboration with suppliers, as the scale up (parallelization) turns out to be not simple. DSM Pharmaceutical Products sees Micronit as one of the suppliers that are capable of this.”

Most read news

Topics

Organizations

Other news from the department research and development

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.