Bayer MaterialScience researchers explore factors influencing weathering performance of two-component polyurethane topcoats

2-component polyurethane coatings exceed industry standards for weatherability

The power of polyurethane topcoats first debuted in the industrial maintenance and marine markets in the mid-1970s as part of a corrosion protection system. Polyurethane topcoats have evolved over the years into a versatile technology that can be formulated to create low VOC coatings and productivity enhancing coatings, as well as long-lasting, cost-effective coatings. However, recently there has been a call for ultra-high weathering performance topcoats for applications such as sports facilities, water tanks and bridges where coating systems are expected to provide aesthetic appeal along with corrosion protection.

In a quest to explore whether current weathering performance specifications for two-component polyurethane topcoats - such as SSPC Paint Specification No. 36 - go far enough in defining the highest level of polyurethane performance available for these demanding applications, Edward P. Squiller, director, Specialty Coatings and Kurt Best, senior scientist, both of Bayer MaterialScience (BMS) LLC, authored a paper: 2-Component Polyurethane Topcoats - Formulating Variables Affecting Weathering Performance. The authors discussed their paper at the recent 2008 Paint and Coatings Expo.

There are many potential variables in typical corrosion protection topcoat formulations that influence performance and application characteristics, as well as the cost structure of the coating. These variables include isocyanate index and resin selection, which play a major role in determining the weatherability of the final product.

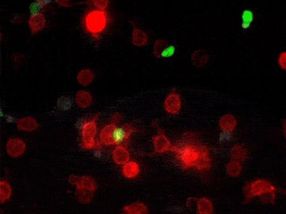

In their paper, the authors compare some key formulating variables of aliphatic polyurethane topcoats and their resulting performance in an accelerated weathering study. Aliphatic polyisocyanates traditionally result in topcoats with much better outdoor weathering characteristics versus aromatic polyisocyanates, and are primarily used in outdoor topcoat applications in which gloss and color retention are required.

Through their research, the authors discovered that all of the polyurethane topcoats tested met the highest performance level specified by SSPC Paint Spec. #36 with regard to loss of gloss and yellowing, therefore concluding that the topcoats are capable of achieving a much higher performance standard. However, the authors caution against reading too much into just one accelerated test method relative to other important considerations.

Organizations

Other news from the department science

These products might interest you

OCA 200 by DataPhysics

Using contact angle meter to comprehensively characterise wetting behaviour, solids, and liquids

With its intuitive software and as a modular system, the OCA 200 answers to all customers’ needs

Dursan by SilcoTek

Innovative coating revolutionizes LC analysis

Stainless steel components with the performance of PEEK - inert, robust and cost-effective

Tailor-made products for specific applications by IPC Process Center

Granulates and pellets - we develop and manufacture the perfect solution for you

Agglomeration of powders, pelletising of powders and fluids, coating with melts and polymers

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.