Kuraray Co., Ltd. Announces the SEPTON V Series New Hydrogenated Styrene Thermoplastic Elastomer with Reactive Hard Blocks

Tokyo, Japan - Kuraray Co., Ltd. announced the development of the SEPTON V Series, hydrogenated styrene thermoplastic elastomers (hereafter, "hydrogenated styrene elastomers") that will provide compounds with improved heat resistance and oil resistance.

Typical hydrogenated styrene elastomers are composed of hard block (styrene) and soft block (ethylene, propylene, butylene, etc.) polymers. As with other plastics, they are easily processed when heated. These elastomers also have the elasticity of rubber, which allows them to be used as a substitute for vulcanized rubber and flexible polyvinyl chloride. The world market for hydrogenated styrene elastomers is approximately 100,000 tons per year, with a growth rate of approximately 10% per year (Kuraray estimate). These resins are easily compounded with polypropylene, process oil and other ingredients, or can be dynamically cross-linked in the compounding process. However, when these resins are cross-linked, only the soft block cross-links, which means that the heat and oil resistances are limited. Markets in which these characteristics are important still use vulcanized rubber.

Unlike earlier SEPTON products, the SEPTON V Series contains a crosslinkable hard block and makes it reactive. Kuraray has also developed special compounding technology which makes it possible to cross-link the hard block as well as the soft block during compounding. This provides a compound with higher heat and oil resistance, which makes them suitable for use in markets in which vulcanized rubber is used such as automotive sealing material and construction materials.

Kuraray is scheduled to commence production of the SEPTON V Series in the summer of 2004. The new product will be marketed together with the compounding technology Kuraray has developed. As various compounders combine Kuraray's compounding technology with their own, it can be expected that development will accelerate and the number of applications will increase. For this reason, Kuraray will maintain close ties to these compounders, and hopes to nurture this market in the near future to the scope of 5,000 tons per year. With this new material as a core product, Kuraray will work to expand its elastomer business.

Other news from the department business & finance

These products might interest you

Spinsolve Benchtop NMR by Magritek

Spinsolve Benchtop NMR

Spinsolve is a revolutionary multinuclear NMR spectrometer that provides the best performance

Eclipse by Wyatt Technology

FFF-MALS system for separation and characterization of macromolecules and nanoparticles

The latest and most innovative FFF system designed for highest usability, robustness and data quality

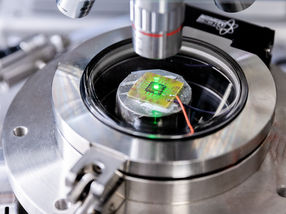

HYPERION II by Bruker

FT-IR and IR laser imaging (QCL) microscope for research and development

Analyze macroscopic samples with microscopic resolution (5 µm) in seconds

Get the chemical industry in your inbox

From now on, don't miss a thing: Our newsletter for the chemical industry, analytics, lab technology and process engineering brings you up to date every Tuesday and Thursday. The latest industry news, product highlights and innovations - compact and easy to understand in your inbox. Researched by us so you don't have to.