Fire and flame for new surfaces

The printing, coating and bonding of plastics requires the surface to be pre-treated. Flame treatment is one way to achieve this so-called activation. It is currently being used in many industrial sectors and has considerable potential for development. The Fraunhofer Institute for Applied Polymer Research IAP in Potsdam and the Italian company esse CI are uniting their expertise in surface chemistry and machine engineering in order to clearly expand the opportunities provided by flame treatment and to extend the range of surface properties. Interested companies can take part in the development of this technology and help advance its industrialization.

A flame treatment facility in operation.

esse CI

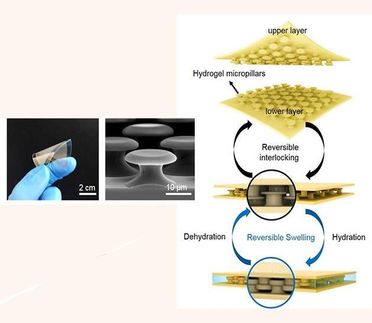

When plastic bumpers were first introduced they were black because paint did not adhere very well to the surface. Today these plastic components can easily be painted in the colour of the car body. This is all down to a change in surface properties. The surface is pre-treated with the help of an electric charge or flame. During flame treatment, reactive components form during the burning process. This initiates oxidation on the material being treated; however, this oxidation is unspecific and can only be altered in quantity, not in typology. This means there is considerable room for the development of optimized high-performance applications. Both partners are looking to explore new avenues in flame treatment.

Flame treatment meets surface chemistry

”Our aim is to expand the range of functionalization and produce bespoke surfaces for special applications. For example, we produce specific functional groups on the surface as reaction partners for reactive adhesives. This enables us to create a high-performance composite with a much better adhesion than with ordinary activation”, explains Dr. Andreas Holländer, a specialist for surface technologies at the Fraunhofer IAP.

The partners combine the Fraunhofer IAP’s expertise in surface chemistry with esse CI’s know-how in flame treatment. They hope to utilise the energy of the flame for chemical processes that go beyond simple oxidation. This requires chemicals to be added to the flame, for example in the form of gases, vapours or aerosols. The studies are conducted in a plastic film processing plant at the Fraunhofer IAP. “Here we test which effects are produced by the chemicals. Using this knowledge, esse Ci’s mechanical engineers enhance the next generation of equipment”, says Holländer.

Augusto Angeli, chairman of esse Ci, is pleased: “By installing our flame treatment system in the demonstration plant in Potsdam we are able to demonstrate the technology’s capabilities to potential customers. “ Stefano Mancinelli, process and sales manager, adds: “We are advancing the development of the technology with the aim of developing new market segments. “ The medium-sized company from Narni, Italy produces equipment for surface treatment on plastic films, cards, aluminium foil and 3D objects. Their flame treatment technology is already being used in a range of industrial applications.

Rapid industrialization with new partners

In order to facilitate the industrialization of this new generation of flame treatment systems, interested companies are invited to take part this year in the project. They can influence the detailed planning, for example, of materials and process parameters, and receive first-hand information and research results. The Fraunhofer IAP and esse CI also provide workshops on the technology, equipment and project results.

Most read news

Other news from the department science

These products might interest you

Dursan by SilcoTek

Innovative coating revolutionizes LC analysis

Stainless steel components with the performance of PEEK - inert, robust and cost-effective

OCA 200 by DataPhysics

Using contact angle meter to comprehensively characterise wetting behaviour, solids, and liquids

With its intuitive software and as a modular system, the OCA 200 answers to all customers’ needs

Tailor-made products for specific applications by IPC Process Center

Granulates and pellets - we develop and manufacture the perfect solution for you

Agglomeration of powders, pelletising of powders and fluids, coating with melts and polymers

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.