Color pigments from Krefeld-Uerdingen have been making the world a more colorful place for 90 years

World’s biggest iron oxide plant has manufactured more than 13 million metric tons of color pigments since 1926

Specialty chemicals company LANXESS produces iron oxide and chrome oxide pigments for numerous applications in the world’s largest production plant for inorganic color pigments in Krefeld-Uerdingen – and has been doing so for 90 years. Whether in the paint on the Eiffel Tower in Paris, the red asphalt in front of Buckingham Palace in London or numerous products we encounter in our day-to-day lives – pigments from LANXESS are in use all around the world. What began very modestly 90 years ago has turned into a genuine success story. Since its launch in 1926, more than 13 million metric tons of pigments have left the plant in Krefeld-Uerdingen.

The Eiffel tower: Bayferrox pigments from the specialty chemicals group LANXESS AG provide the color for the Paris trademark’s high-grade anticorrosion coating.

Foto: Christian Bamale

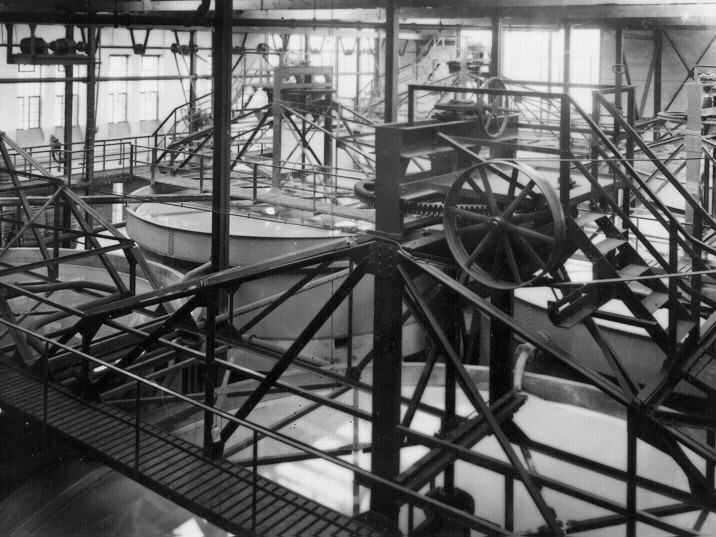

Thickener in Uerdingen site’s iron oxide plant 1 in 1929 – three years after production launch.

Foto: Bayer AG

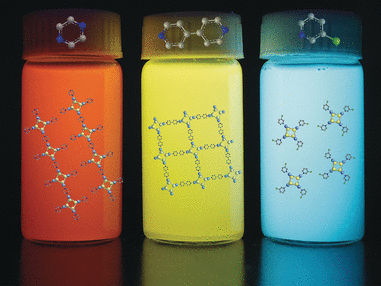

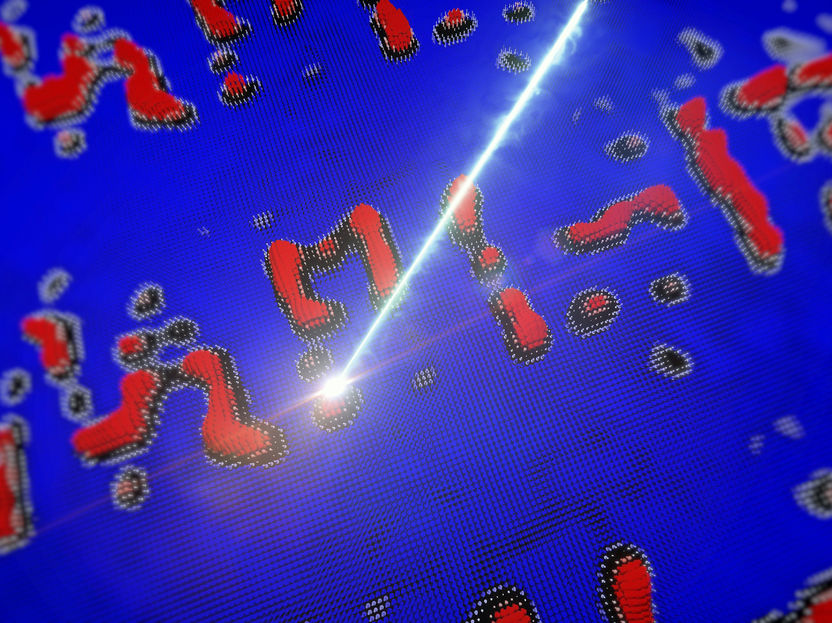

Production of yellow iron oxide pigments at the LANXESS site in Krefeld-Uerdingen, Germany.

Foto: LANXESS AG

A fast-paced story

It was back in the 1920s that Julius Laux, head of the aniline plant in Uerdingen, started searching for ways of using the iron oxide pastes that were a waste product of aniline manufacturing. In 1925, he discovered that the presence of salt solutions led to the formation of intensely colored oxides that were ideal for use as pigments. There were just one and a half years between this discovery and the start of production. After manufacturing 1,200 metric tons of iron oxides in 1926, production quickly grew to more than 5,000 metric tons in 1927.

Just a short time later, synthetic iron oxides had established a firm place on the market and were being used primarily to color linoleum, surface coatings and construction materials. In the 1960s, annual production volumes climbed to more than 100,000 metric tons. The range has also grown considerably over the decades. While customers could choose from 25 colors in 1931, the current range extends to more than 100.

In 1976, the iron oxides from Uerdingen got their own special name and, since then, Bayferrox has been the most important global umbrella brand for the pigments. The products are distinguished by their high quality and simple and environmentally compatible processing.

A key product development came in the 1990s with the introduction of microgranules, which support low-dust handling and are free flowing for metering purposes.

The latest groundbreaking innovation is the new plant in Ningbo, China. IPG – including staff at the Krefeld site – developed a completely new technology, known as the “Ningbo Process”, for the plant, which has since become another global benchmark for sustainable iron oxide production.

LANXESS launches new initiative for young people in Krefeld

Besides production itself, LANXESS also places a very high value on its links with the local community. “We want to find a special way of thanking the city for the decades of outstanding cooperation we have had,” explained Jörg Hellwig, head of the LANXESS Inorganic Pigments business unit (IPG) at a celebration marking the 90th anniversary of the Uerdingen production facility for iron oxide pigments. He was joined by Krefeld’s Lord Mayor, Frank Meyer, as he announced the launch of the new “Besser Lernen” (Learn better) initiative for educational institutions and youth organizations in Krefeld. With the Lord Mayor as its patron and a total fund of EUR 50,000, the initiative will support projects run by educational institutions and youth organizations that use color schemes and other measures to improve the learning environment or care services for young people. Public educational institutions, clubs and initiatives can now put forward projects that are being run in Krefeld and involve total costs up to EUR 10,000.

The winners will be selected and announced by a specially convened judging panel. They will be announced before the end of the year. The conditions of participation and judging criteria have been published online.

“We are very happy that a global company like LANXESS has such an important base in our city and that those in charge are so committed to maintaining the close historic links between the company and Krefeld,” said Lord Mayor Meyer. “The ‘Besser Lernen’ initiative is a wonderful example of a creative way that a company can do something beneficial and demonstrate its commitment to its city and the people who live there.”

Geared toward customers and competitiveness

IPG supplies some 5,000 users worldwide with pigments that are used to color a wide variety of products. “As our customers see it, our decades of experience in manufacturing quality products and in process development and optimization sets us apart from many of our competitors,” remarked Hellwig. At its most important site in Krefeld-Uerdingen, the business unit harnesses the entire value-added chain for iron oxide production – from synthesis through to packaging. “One very special advantage of the site is its strong level of plant automation, which enables maximum production output and thus excellent cost efficiency. What’s more, here in Krefeld, we also have extremely well-trained staff and very high and sustainable standards as regards both environmental considerations and production, giving us a key edge over the competition internationally,” said Hellwig. “The most important thing, however, is that we have a team that is extremely good at what it does, is full of ideas and is highly motivated – without that we would never have been able to achieve the success that we now want to carry forward.”

At the Krefeld-Uerdingen site alone, LANXESS produces more than 280,000 metric tons of color pigments a year, with the global figure at 375,000 metric tons – and growing. LANXESS is committed to what is its second-largest production site worldwide. Between 2005 and 2015, the specialty chemicals company invested some EUR 420 million in the facility, approximately EUR 200 million of which benefited pigment production alone. “Besides the quality and performance of our products, the innovative capabilities and creativity of our employees have played an important part in helping our pigments under the now world-famous Bayferrox brand to carve out a leading position on the market over the past nine decades,” remarked Hellwig.

LANXESS takes part in the “Week of Industry”

The LANXESS celebration to mark the 90-year history of iron oxide production in Krefeld-Uerdingen is one of 364 different activities that are being held throughout Germany between September 17 and 29 as part of the “Week of Industry.” The “Week of Industry” is an initiative by the “Zukunft der Industrie” (Future of Industry) group. The group brings together 15 separate business associations and trade unions and the German Federal Ministry for Economic Affairs and Energy. Over the course of the week, businesses, locations and workforces are presenting themselves as major employers, engines for innovation and drivers of output in the region. The overarching goal of the partners in the group is to safeguard Germany’s long-term future as an industrial location and boost industrial competitiveness.