Fraunhofer IST sells its first pilot-scale unit for patterned plasma treatment of polymer films

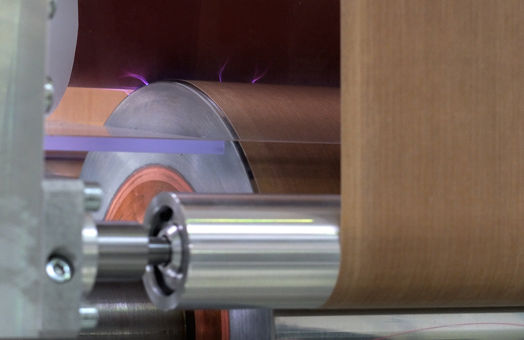

Many years went into development, then came six months with the screwdriver, of tweaking and testing, and now they are finally there: the scientists of the Fraunhofer Institute for Surface Engineering and Thin Films in Braunschweig together with their partners GRT GmbH & Co. KG, Systec System- und Anlagentechnik GmbH & Co. KG, WLW Wagner Leisner Wolter GmbH and Schuler Konstruktionen GmbH & Co. KG have built their first reel-to-reel plasma printing system and delivered it to a Japanese company in the Osaka area.

Reel-to-rell plasma treatment of polymer films.

© Fraunhofer IST

The manufacturer of functional polymer films and sheets uses the system for research and development purposes. "With this system, films measuring up to 450 mm in width can be continuously treated with plasma, and very specifically only at the desired locations", says Dr. Michael Thomas, the project leader and head of department at the Fraunhofer IST. A further scaling-up is in the planning stage.

‘Plasma printing’ exploits the nature of the fourth state of matter – plasma - with its chemically reactive components as a tool to produce micropatterned surfaces. For instance, the wettability of polymer surfaces can be area-selectively adjusted to create hydrophilic or hydrophobic areas, that is, water-loving or water-repellent areas. Water-loving areas were produced with surface energies up to 72 mN/m.

With the plasma, furthermore, plastics can be activated without elaborate chemical etching processes in an environmentally friendly manner such that structured, well-adherent metallization is possible in a subsequent step. 'Plasma printing' is also particularly suitable for the selective functionalization of surfaces with reactive groups which permit a subsequent chemical coupling reaction. There is a need for such functionalizations in, among other fields, the life sciences, for example, in the development of biochips and biosensors.

Most read news

Other news from the department business & finance

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.