Researchers Develop a New Type of X-ray Lens

A lamellar lens prototype has been successfully tested at DESY

Researchers have taken an important step towards developing a new X-ray lens made of diamond. A team of scientists from the Technische Universität (TU) Dresden and Technische Universität Chemnitz as well as from DESY have successfully tested a new lens design. The group working with DESY Leading Scientist, Professor Christian Schroer, presents the results in the scientific journal Applied Physics Letters.

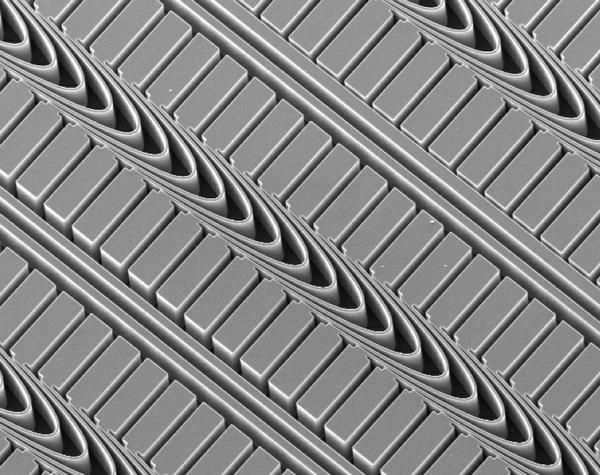

Scanning electron micrograph of a one-dimensionally focussing lamellar lens. Each lamella is about 1.5 microns thick.

Frank Seiboth/TU Dresden

With bright X-ray light sources like DESY’s PETRA III, scientists X-ray various materials – from biomolecules to solar cells and artificial magma – in order to explore their inner structures. It is often necessary to focus the intense X-ray light in such studies. “In X-ray microscopy, the spatial resolution is often limited by X-ray optics and not, as in optical microscopy, by the wavelength of the light used,” explains Schroer, scientific head of PETRA III.

X-rays cannot be focussed with standard lenses in the manner visible light can. The scientists instead use specialized lenses for this purpose, which are currently produced with silicon. “A fundamental problem with these lenses is the high absorption of the radiation within the lens material,” says Dr. Gerald Falkenberg, head of the experiments station P06, where the tests were carried out. “This decreases the brightness of the X-ray beam and lowers the X-ray microscope’s resolution.” The scientists therefore wish to make the lenses as thin as possible and from the most dense but X-ray permeable material. Lenses made of carbon in the form of diamond would be optimal.

Schroer’s team has now devised a new form of lens, which no longer possesses a concave profile but consists of fine, curved lamellae. “The curves of the lamellae thereby ensure the focussing of X-ray light,” explains Maria Scholz, who researched the lens for her Master’s thesis. The lamellae are still made of silicon, which is coated with a denser but more X-ray permeable material. The advantage is that highly developed silicon manufacturing technology can be used while new materials can be applied using simpler coating procedures.

The scientists coated the lamellae of the prototype with aluminium oxide, which is superior to silicon for X-ray optics. “The lamellae are to be later coated with far more X-ray permeable carbon,” explains Frank Seiboth from the TU Dresden, first author of the study. “The silicon is to be removed in a later step so that only the diamond lamellae remain.”

The aluminium oxide-silicon prototype could focus the bright PETRA III X-ray light on a surface measuring 164 by 296 nanometres in tests. A nanometre is a millionth of a millimetre. The small X-ray area was therefore about 50,000 times smaller than the cross-section of a human hair. X-ray light can already be focussed even more intensely with other lenses, but the prototype test impressively demonstrates that the new lens design functions as was intended.

“The prototype achieves the optimal computational focussing up to a factor of 2," says Schroer. Studies with the electron microscope demonstrate irregularities in the lamellae's thickness that explain this deviation. This can be optimized with existing technology. "We are confident that a pure diamond lens will end up achieving a focal area of 17 by 28 nanometres and can let pass up to 35 per cent the X-ray light – this is ten times the transmission of a pure silicon lens.”

Original publication

Other news from the department science

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.