Supersonic spray delivers high quality graphene layer

A simple, inexpensive spray method that deposits a graphene film can heal manufacturing defects and produce a high quality graphene layer on a range of substrates, report researchers at the University of Illinois at Chicago and Korea University. Their study is published in Advanced Functional Materials.

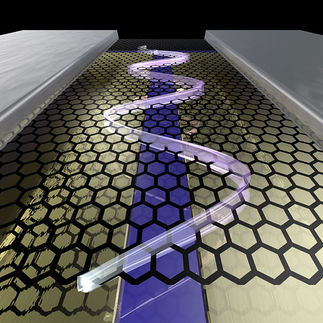

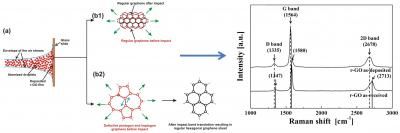

Using a supersonic spray, graphene flakes with deformed pentagonal and heptagonal structures stretch on impact and spring into a perfect hexagonal graphene lattice. This opens the way to scale up from the microscopic to large scale applications.

Suman Sinha-Ray

Although the potential uses for graphene seem limitless, there has been no easy way to scale up from microscopic to large-scale applications without introducing defects, says Alexander Yarin, UIC professor of mechanical and industrial engineering and co-principal investigator on the study.

"Normally, graphene is produced in small flakes, and even these small flakes have defects," Yarin said. Worse, when you try to deposit them onto a large-scale area, defects increase, and graphene's useful properties its "magic" are lost, he said.

Yarin first turned to solving how to deposit graphene flakes to form a consistent layer without any clumps or spaces. He went to Sam S. Yoon, professor of mechanical engineering at Korea University and co-principal investigator on the study.

Yoon had been working with a unique kinetic spray deposition system that exploits the supersonic acceleration of droplets through a Laval nozzle. Although Yoon was working with different materials, Yarin believed his method might be used to deposit graphene flakes into a smooth layer.

Their supersonic spray system produces very small droplets of graphene suspension, which disperse evenly, evaporate rapidly, and reduce the tendency of the graphene flakes to aggregate.

But to the researchers' surprise, defects inherent in the flakes themselves disappeared, as a by-product of the spray method. The result was a higher quality graphene layer, as found in the analysis by another collaborator, Suman Sinha-Ray, senior researcher at United States Gypsum and UIC adjunct professor of mechanical and industrial engineering.

The researchers demonstrated that the energy of the impact stretches the graphene and restructures the arrangement of its carbon atoms into the perfect hexagons of flawless graphene.

Most read news

Other news from the department science

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.