Lyondell Announces Plans to Build One-Step Direct Oxidation Propylene Oxide Pilot Plant

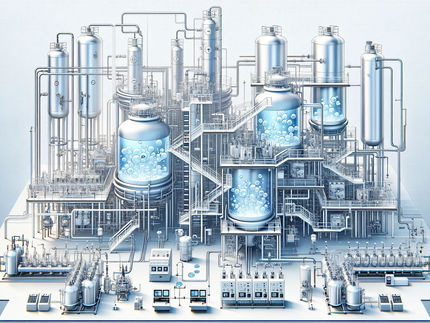

HOUSTON, Oct. 8 - Lyondell Chemical Company, today announced it is building an integrated pilot plant to further develop its proprietary one-step, direct Oxidation PO technology.

The pilot plant will be built at Lyondell's Technology Center in Newtown Square, Pennsylvania, and will be the final demonstration of the technology before commercialization. Lyondell's operating capacity for PO is about 4 billion pounds per year.

"We have been working for many years on a technology that will produce PO in one step without requiring an auxiliary feedstock facility, such as a hydrogen peroxide plant. The added benefit of our technology is that it produces PO without a co-product such as styrene or tertiary butyl alcohol," said Ed Dineen, Lyondell senior vice president of chemicals and polymers. "Now that our extensive testing of the lab-scale process is complete, we are ready to pilot the process on a much larger scale."

Currently, the three leading commercial methods of PO production are the propylene oxide/styrene monomer (POSM) process, the propylene oxide/t-butyl alcohol (PO/TBA) process (both invented by Lyondell), and the chlorohydrin process. All three of these processes require greater capital investment to build a plant than the direct oxidation technology.

"We believe the POSM process is the best technology available today to produce PO because of its significantly lower cash costs. We continue to make improvements to this technology," said Dineen. "At the same time, we also believe this new one-step direct PO technology offers significant economic advantages.

"A direct PO plant costs less to build than a POSM, PO/TBA or chlorohydrin plant. And because there is no co-product, our investment decisions will not be influenced by market conditions for the co-product," added Dineen.

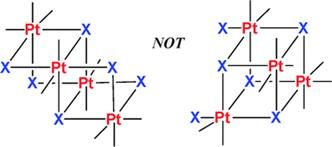

Lyondell has spent more than 40 years exploring PO process technologies to identify the most efficient and lowest-cost options. Since 1990, Lyondell has secured more than 130 U.S. patents in the PO area.

"The potential offered by one-step direct PO technology is very exciting, and will complement Lyondell's portfolio of PO technologies that provides commercial and operational flexibility unmatched in the industry. With these technologies, we can use the process that will be the most viable in any given market," said Peter Gaines, Lyondell's global vice president, oxygenated chemicals.

"We continue to work with Sumitomo Chemical Company, Ltd., our partner in the Nihon Oxirane Co., LTD. joint venture, on a pioneering PO/Cumene plant in Japan, which is scheduled to be operational in 2003. This technology, developed by Sumitomo as part of an ongoing technology co-operation with Lyondell, is particularly suited to the Japanese market where there is currently an oversupply of styrene," Gaines said.

Lyondell also is building a new POSM plant in Rotterdam, The Netherlands, scheduled for start-up in 2003. It is the 11th PO plant built by Lyondell, and will be jointly owned by Lyondell and Bayer.

Most read news

Topics

Organizations

Other news from the department business & finance

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.