Frost & Sullivan forecasts steady growth for global mechanical seals market

Expansion into emerging BRIC economies to be major driver of growth in the current economic environment

Holding fast against the ongoing economic turmoil, the global mechanical seals market is expected to grow at a steady pace over the long-term across all major end-user industries. Continued patronage from the oil and gas, chemical and pharmaceutical industries, together with the expanding base of pumps and compressors in the emerging BRIC economies, will stand the market in good stead.

New analysis from Frost & Sullivan, Global Mechanical Seals Market, finds that the market earned revenues of approximately $2,691.5 million in 2012 and estimates this to reach $3,558.4 million in 2015.

“Expansion into emerging economies such as Brazil, Russia, China and India is expected to be a major driver of growth in the current economic environment,” noted Frost & Sullivan Industrial Automation & Process Control Program Manager Ashwin Annareddy. “With the market in North America and Western Europe reaching maturity levels, the focus is expected to shift to after-sales services and product enhancements.”

Well-established EU norms for energy recycling and efficiency have placed the onus on pump suppliers to consistently introduce novel product features. The EU also has strict guidelines related to fugitive emissions through equipment leaks. In America, the Environmental Protection Agency (EPA) air emission standards require specific work practices for equipment leak detection and repair.

Manufacturers in these regions therefore have to improve product reliability, functionality and lifecycle. Demand in these mature regional markets will be sustained on a platform of innovative design features, improved pump and motor efficiencies, higher price-performance ratio and prompt after-sales service.

One of the key threats to market growth is the increased adoption of seal-less magnetic drive pumps. Oil and gas, chemical and petrochemical industries require mechanical seals to be API 682 standard compliant. However, compliance to this standard requires substantial R&D investment, which regional seal manufacturers are unable to provide.

Increasing customer satisfaction also poses a significant challenge to pump manufacturers. End users now expect not just timely delivery of a high-quality product, but an array of effective services to back their product purchase.

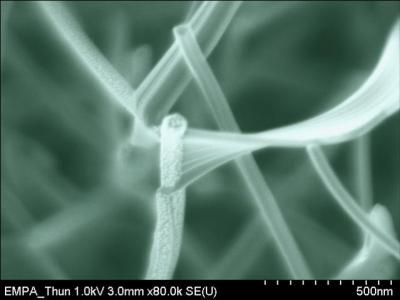

“With mechanical seal reliability being a critical purchase criterion, R&D into different materials of construction, value-based design engineering, on-site system support and value sharing hold the key for effective communication of enhanced value to end users,” advised Annareddy. “Overall, manufacturers need to develop a broad product portfolio and strong service backup, while boosting penetration into emerging regions.”

Most read news

Other news from the department business & finance

These products might interest you

Typ CNF / Typ CAM by Hermetic-Pumpen

Reliable pump technology for hazardous applications

Shaft seal-free pumps for maximum reliability and safety

Peristaltic Pumps by AHF analysentechnik

Reliable and Low-pulsation Transport of Liquids in Laboratory Analysis

AZURA Analytical HPLC by KNAUER

Maximize your analytical efficiency with customized HPLC system solutions

Let your application define your analytical system solution

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.