New Foxboro pH Sensor Line Doubles Service Life, Reduces Costs in Demanding Applications

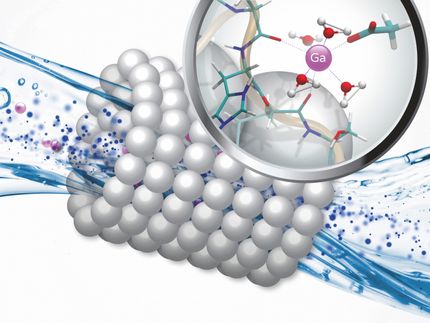

Foxboro, a unit of Invensys Production Management, has introduced a new family of pH sensors designed to improve operation in traditional problem areas within harsh process applications. As demonstrated at the Invensys Showcase Conference and EXPO, the new DolpHin(TM) sensor line incorporates patent pending measurement and reference technology that has proven to perform more than twice as long as traditional pH sensors in harsh applications. The new Foxboro pH sensor line also contributes to cost savings in maintenance and equipment by significantly reducing cleaning, calibrating, and replacement requirements.

The unique pH glass formulation provides superior measurement stability and accuracy, and longer service life in high temperature applications up to 250 degrees F. (121 degrees C). The pH glass also increases response speed up to five times and allows longer duty cycles, compared to conventional sensors. The new reference electrode construction includes an ion barrier to protect and stabilize the reference potential in harsh conditions. Both electrodes are packaged in a rugged mechanical housing that facilitates installation, removal, cleaning, and calibration, reducing maintenance time and costs.

The DolpHin line is available in flat and domed versions. The flat glass design promotes self-cleaning for longer service before operator intervention. The domed glass design operates longer and more accurately at high temperatures than conventional process pH sensors.

The DolpHin Series sensors are designed for process industry applications that span the entire pH scale, have strong chemical concentrations and high solids, run at high temperature, and cycle from high to low temperature. These include:

- Chemical and petrochemical manufacturing in reactors, scrubbers, etc.

- Pulp and paper manufacturing in bleaching, thin stock, thick stock, and head box

- Dairy processes for cheese processing and CIP (clean in place)

- Electronics and metals processes involving etching, slurries, and metal finishing

- Industrial and municipal waste water treatment, from incoming to final effluent

Other news from the department research and development

These products might interest you

Most read news

More news from our other portals

See the theme worlds for related content

Topic world Sensor technology

Sensor technology has revolutionized the chemical industry by providing accurate, timely and reliable data across a wide range of processes. From monitoring critical parameters in production lines to early detection of potential malfunctions or hazards, sensors are the silent sentinels that ensure quality, efficiency and safety.

Topic world Sensor technology

Sensor technology has revolutionized the chemical industry by providing accurate, timely and reliable data across a wide range of processes. From monitoring critical parameters in production lines to early detection of potential malfunctions or hazards, sensors are the silent sentinels that ensure quality, efficiency and safety.