BioBoost – Boost of biomass-based energy

Production of high-quality engine-compatible fuels and chemicals

Advertisement

Six research institutions and seven industrial partners from all over Europe will participate. Research under BioBoost will complement the bioliq® concept of KIT, which is designed for the production of designer fuels for diesel and Otto engines from biogenous residues, e.g., straw.

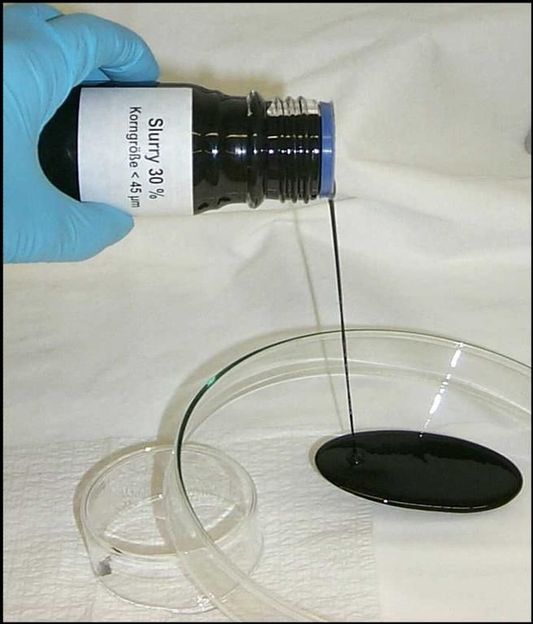

BioSynCrude: Energy density of this intermediate product is up to ten times higher than that of the feedstocks.

IKFT, KIT

Europe is pinning its hopes on energy resources based on residual biomass. BioBoost is one of only two projects for the development of new energy carriers, which were chosen for funding under the 7th EU Research Framework Programme from numerous proposals. The project will have a duration of three and a half years and be funded by the EU with a total amount of nearly EUR 5.1 million. Funding granted to KIT will amount to nearly one million euros. "Due to its broader access to usable residues and a broader spectrum of use of the energy carriers, this project fits excellently to our bioliq® project in Karlsruhe. Both projects profit from each other in an ideal manner," explains BioBoost project coordinator Dr. Ralph Stahl from the Institute of Catalysis Research and Technology (IKFT) of KIT.

BioBoost will focus on the production of various energy-rich intermediate products from biogenous residues and on testing and evaluating them with regard to their usability like e.g. in the bioliq® process . In addition to the BioSynCrude® generated by flash pyrolysis in the bioliq® process, BioBoost will produce, optimize, and evaluate other intermediate products too. Moreover, the project will cover the analysis of economic efficiency of the complete process, optimization of logistics chains, and the investigation of environmental compatibility. The objective is to significantly improve the efficiency of the use of biomass and residues in the future.

The process consists of several steps. The first step serves to concentrate the energy, as the residual biomass, e.g., straw, arises in a spatially distributed manner and contains a very small amount of energy. At decentralized facilities, biogenous residues are converted into coke and oil by pyrolysis or carbonization. These products are mixed to form energy-rich intermediate products that contain up to 90% of the energy stored in the biomass. They can be transported in an economically efficient manner to a central location for further processing. There, the energy carriers are subjected to large-scale use in a second step. In addition to the production of customized fuels, such as diesel, gasoline, or kerosene, scientists will also investigate the production of chemicals like methanol, ethylene, and propylene as well as plastics. Generation of electricity and heat from the energy-rich intermediate product also is subject of BioBoost.