UV-transparent coating for image sensors

Image sensors as used in cell phones are partially color-blind. This is because of their coating, which prevents UV light from passing through. CMOS chips have as a result not been suitable for spectroscopy up to now. A new production process makes the coating transparent – and the sensors suitable for special applications.

They have been used as standard in multimedia electronics for a long time, and now they are making rapid inroads in high performance applications: CMOS image sensors are no longer only used in cell phones and digital cameras. The automotive industry, for instance, has discovered the potential of optical semiconductor chips and is increasingly using them in driver assistance systems – from parking aids and road lane detection to blind-spot warning devices. In special applications, however, the sensors that convert light into electrical signals have to cope with diffi cult operating conditions, for example high temperatures and moisture.

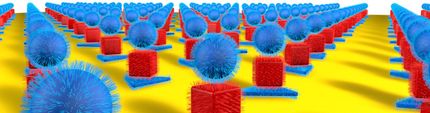

For this reason, CMOS devices are covered with a silicon nitride coating. This chemical compound forms hard layers which protect the sensor from mechanical influences and the penetration of moisture and other impurities. The protective coating is applied to the sensor in the final stage of CMOS semiconductor production. The process is called passivation, and is an industry requirement. Unfortunately, up to now this passivation has entailed a problem: the silicon nitride coating limits the range of optical applications because it is impermeable to light in the UV and blue spectral range. CMOS sensors for high-performance applications, used in special cameras are therefore partially color-blind.

Scientists at the Fraunhofer Institute for Microelectronic Circuits and Systems IMS in Duisburg have found a solution to this problem: “We’ve developed a new process step,” says Werner Brockherde, head of department at Fraunhofer IMS, “that allows us to produce a protective coating with the same properties but which is permeable to blue and UV light.” The trick is to increase the proportion of nitrogen in the coating. “This reduces the absorption of shortwave light,” explains Brockherde.

In simplified terms, the new coating material will absorbless light of an energy higher than blue light, which means the sensor becomes more sensitive at the blue and UV range. “This makes CMOS image sensors suitable for use in wavelength ranges down to 200 nanometers,” states Brockherde. “With standard passivation the limit was about 450 nanometers.” To change the structure of the silicon nitride for the coating, the Fraunhofer research scientists had to fine-tune the deposition parameters such as pressure and temperature.

With this process development the experts have expanded the range of applications for CMOS image technology. This could revolutionize UV spectroscopic methods, which are used in laboratories around the world, significantly improving their accuracy. Likewise, CMOS image sensors stand to take up a new role in professional microscopy, e.g. in fluorescence microscopes, providing scientists with images of even greater detail.

Other news from the department science

These products might interest you

SprayMaster inspex by LaVision

Quality Control for Your Spraying Process Through Digital Spray and Particle Analysis

Reliable, Automated, Digital - The Geometry Measurement of Your Spraying Process in Real Time

FireSting-PRO by PyroScience

New fiber optic measuring device: Precise measurements even in the smallest volumes

Measure pH, oxygen and temperature even under sterile conditions

VEGAPULS | VEGABAR | VEGASWING by VEGA Grieshaber

Cyber-safe level measurement - here's how it works

Find out more about the unique sensor for liquid and solid media

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

See the theme worlds for related content

Topic World Spectroscopy

Investigation with spectroscopy gives us unique insights into the composition and structure of materials. From UV-Vis spectroscopy to infrared and Raman spectroscopy to fluorescence and atomic absorption spectroscopy, spectroscopy offers us a wide range of analytical techniques to precisely characterize substances. Immerse yourself in the fascinating world of spectroscopy!

Topic World Spectroscopy

Investigation with spectroscopy gives us unique insights into the composition and structure of materials. From UV-Vis spectroscopy to infrared and Raman spectroscopy to fluorescence and atomic absorption spectroscopy, spectroscopy offers us a wide range of analytical techniques to precisely characterize substances. Immerse yourself in the fascinating world of spectroscopy!

Topic world Sensor technology

Sensor technology has revolutionized the chemical industry by providing accurate, timely and reliable data across a wide range of processes. From monitoring critical parameters in production lines to early detection of potential malfunctions or hazards, sensors are the silent sentinels that ensure quality, efficiency and safety.

Topic world Sensor technology

Sensor technology has revolutionized the chemical industry by providing accurate, timely and reliable data across a wide range of processes. From monitoring critical parameters in production lines to early detection of potential malfunctions or hazards, sensors are the silent sentinels that ensure quality, efficiency and safety.