Agilent Technologies and Mississippi State University Team Up to Test Gulf Seafood for Oil Contamination

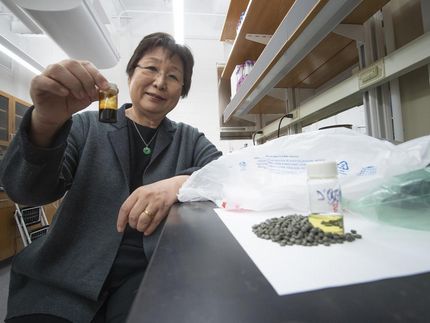

Agilent Technologies Inc. and Mississippi State University (MSU) announced a new analytical method developed by State Chemical Lab scientists at MSU that will be used to test seafood from the Gulf of Mexico for evidence of oil contamination, pending review from the U.S. food and Drug Administration (FDA).

Mississippi State University recently received a boost for the new method when Agilent installed a 7000 Series GC/MS/MS PAH Analyzer that determines levels of polycyclic aromatic hydrocarbons (PAHs), the primary oil contaminants that affect seafood. Agilent engineers completed setup of the new instrument the first week of July.

“Repetition and precision in the testing process are essential,” said Associate Professor Kang Xia, who also serves as director for the Research Division and the Industrial and Agricultural Services Division of the Mississippi State Chemical Lab. “The lab’s current instrument isn’t reliable. It is over 10 years old and has suffered numerous mechanical and software failures due to its advanced age and heavy use. Agilent’s 7000 Series GC/MS/MS PAH Analyzer will prevent this from happening.”

In addition, the Agilent GC/MS/MS PAH Analyzer shortens the turnaround time between testing a sample and providing results to regulatory agencies. With the new piece of equipment, it will take about two and a half days to take 20 samples, run tests and receive the results. This method takes less time than the method currently used by the National Oceanic and Atmospheric Administration (NOAA), which takes five to six days.

“It is critical that Mississippi State and similar research facilities tasked with monitoring the safety of seafood in the Gulf have the most advanced technology available,” said Mike McMullen, president of Agilent’s Chemical Analysis Group. “Agilent has a long history of providing leading technologies in hydrocarbon processing, environmental and food safety testing, all key areas of response in the Gulf. Within weeks of the spill, our scientists had developed turnkey solutions to immediately improve productivity and analytical performance.”

The State Chemical Laboratory expects to submit the new test process to the FDA for review by the end of July. Findings will also be submitted to a peer-reviewed publication.

“Mississippi State’s research, service and outreach are making a difference now, and we will continue to provide long-term leadership as the region recovers from the environmental and economic effects of the oil spill,” said David Shaw, the land-grant institution’s vice president for research and economic development.

Other news from the department research and development

These products might interest you

LAUDA.LIVE by LAUDA

LAUDA.LIVE - The digital platform for your device management

Comprehensive fleet management options for every LAUDA device - with and without IoT connectivity

Limsophy by AAC Infotray

Optimise your laboratory processes with Limsophy LIMS

Seamless integration and process optimisation in laboratory data management

ACD Spectrus Platform by ACD/Labs

Software for Analytical Data Handling in R&D

Standardized Analytical Data Processing & Knowledge Management

ZEISS ZEN core by Carl Zeiss

ZEISS ZEN core - Your Software suite for connected microscopy in laboratory and production

The comprehensive solution for imaging, segmentation, data storage and analysis

ERP-Software GUS-OS Suite by GUS

Holistic ERP solution for companies in the process industry

Integrate all departments for seamless collaboration

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.