Breakthrough in capturing 'hot' CO2 from industrial exhaust

A metal-organic framework is capable of capturing CO2 at extreme temperatures

Industrial plants, such as those that make cement or steel, emit copious amounts of carbon dioxide, a potent greenhouse gas, but the exhaust is too hot for state-of-the-art carbon removal technology. Lots of energy and water are needed to cool the exhaust streams, a requirement that has limited adoption of CO2 capture in some of the most polluting industries.

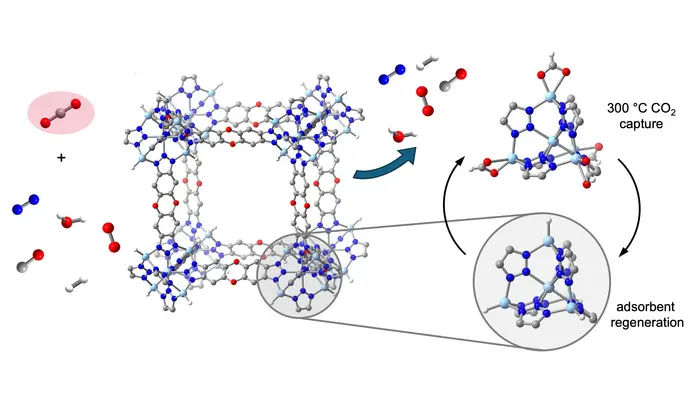

At center left is one of the crystalline building blocks of a thermally stable metal-organic framework (MOF), known as ZnH-MFU-4l, that is able to reversibly and selectively capture the greenhouse gas carbon dioxide from a mix of many industrially relevant gases. CO2 is highlighted at left, among nitrogen, oxygen, hydrogen, carbon monoxide and water molecules. The MOF can capture CO2 over many cycles at 300 C, which is a typical temperature of the exhaust streams from cement and steel plants. The zinc hydride groups in the MOF reversibly bind and release the carbon dioxide molecules (right). Light-blue, gray, blue, red, and white spheres represent Zn, C, N, O, and H atoms, respectively.

Rachel Rohde, Kurtis Carsch and Jeffrey Long, UC Berkeley

Now, chemists at the University of California, Berkeley, have discovered that a porous material can act like a sponge to capture CO2 at temperatures close to those of many industrial exhaust streams. The material — a type of metal-organic framework, or MOF — will be described in a paper to be published in the Nov. 15 print edition of the journal Science.

The dominant method for capturing carbon from power or industrial plant emissions employs liquid amines to absorb CO2, but the reaction only works efficiently at temperatures between 40 and 60 C (100–140 F). Cement manufacturing and steelmaking plants produce exhaust that exceeds 200 C (400 F), and some industrial exhaust approaches 500 C (930 F). New materials that are now being piloted, including a subclass of MOFs with added amines, break down at temperatures above 150 C (300 F) or work far less efficiently.

"A costly infrastructure is necessary to take these hot gas streams and cool them to the appropriate temperatures for existing carbon capture technologies to work," said UC Berkeley postdoctoral fellow Kurtis Carsch, one of two co-first authors of the paper. "Our discovery is poised to change how scientists think about carbon capture. We've found that a MOF can capture carbon dioxide at unprecedentedly high temperatures — temperatures that are relevant for many CO2 emitting processes. This was something that was previously not considered as possible for a porous material."

"Our work moves away from the prevalent study of amine-based carbon capture systems and demonstrates a new mechanism for carbon capture in a MOF that enables high temperature operation," said UC Berkeley graduate student and co-first author Rachel Rohde.

Like all MOFs, the material features a porous, crystalline array of metal ions and organic linkers, with an internal area equivalent to about six football fields per tablespoon — a huge area for adsorbing gases.

"As a result of their unique structures, MOFs have a high density of sites where you can capture and release CO2 under the appropriate conditions," Carsch said.

Under simulated conditions, the researchers showed that this new type of MOF can capture hot CO2 at concentrations relevant to the exhaust streams of cement and steel manufacturing plants, which average 20% to 30% CO2, as well as less concentrated emissions from natural gas power plants, which contain about 4% CO2.

Removing CO2 from industrial and power plant emissions, after which it is either stored underground or used to make fuels or other value-added chemicals, is a key strategy for reducing greenhouse gases that are warming Earth and altering the climate globally. While renewable energy sources are already reducing the need for CO2-emitting, fossil fuel-burning power plants, industrial plants that make intense use of fossil fuels are harder to make sustainable, so flue gas capture is essential.

"We need to start thinking about the CO2 emissions from industries, like making steel and making cement, that are hard to decarbonize, because it's likely that they're still going to be emitting CO2, even as our energy infrastructure shifts more toward renewables," Rohde said.

Moving from amines to metal hydrides

Rohde and Carsch conduct research in the lab of Jeffrey Long, UC Berkeley professor of chemistry, chemical and biomolecular engineering, and of materials science and engineering. Long has been conducting research on CO2-adsorbing MOFs for more than a decade. His lab created a promising material in 2015 that was further developed by Long's startup company, Mosaic Materials, which in 2022 was acquired by the energy technology company Baker Hughes. This material features amines that capture the CO2; next-generation variants are being tested as alternatives to aqueous amines for CO2 capture in pilot-scale plants, and as a way to capture CO2 directly from ambient air.

But those MOFs, like other porous adsorbents, are ineffective at the elevated temperatures associated with many flue gases, Carsch said.

Amine-based adsorbents, like those developed by Long, have been the focus of carbon capture research for decades. The MOF studied by Rohde, Carsch, Long and their colleagues instead features pores decorated with zinc hydride sites, which also bind CO2. These sites turned out to be surprisingly stable, Rohde said.

"Molecular metal hydrides can be reactive and have low stability," Rohde said. "This material is highly stable and does something called deep carbon capture, which means it can capture 90% or more of the CO2 that it comes into contact with, which is really what you need for point-source capture. And it has CO2 capacities comparable to the amine-appended MOFs, though at much higher temperatures."

Once the MOF is filled with CO2, the CO2 can be removed, or desorbed, by lowering the partial pressure of CO2, either by flushing with a different gas or putting it in a vacuum. The MOF is then ready to be reused for another adsorption cycle.

"Because entropy favors having molecules like CO2 in the gas phase more and more with increasing temperature, it was generally thought to be impossible to capture such molecules with a porous solid at temperatures above 200 C," Long said. "This work shows that with the right functionality — here, zinc hydride sites — rapid, reversible, high-capacity capture of CO2 can indeed be accomplished at high temperatures such as 300 C."

Rohde, Long and their colleagues are exploring variants of this metal hydride MOF to see what other gases they can adsorb, and also modifications that will allow such materials to adsorb even more CO2.

"We’re fortunate to have made this discovery, which has opened up new directions in separation science focused on the design of functional adsorbents that can operate at high temperatures,” said Carsch, who has taken a faculty position in the Department of Chemistry at The University of Texas at Austin. "There’s a tremendous number of ways we can tune the metal ion and linker in MOFs, such that it may be possible to rationally design such adsorbents for other high-temperature gas separation processes relevant to industry and sustainability.”

Original publication

Rachel C. Rohde, Kurtis M. Carsch, Matthew N. Dods, Henry Z. H. Jiang, Alexandra R. McIsaac, Ryan A. Klein, Hyunchul Kwon, Sarah L. Karstens, Yang Wang, Adrian J. Huang, Jordan W. Taylor, Yuto Yabuuchi, Nikolay V. Tkachenko, ... Andrew M. Minor, Jeffrey A. Reimer, Martin Head-Gordon, Craig M. Brown, Jeffrey R. Long; "High-temperature carbon dioxide capture in a porous material with terminal zinc hydride sites"; Science, Volume 386