A turning point in packaging development - with the AI application hub for plastic packaging

Advertisement

The AI application hub for sustainable packaging development through the use of artificial intelligence, funded by the Federal Ministry of Research and Education, is presenting its first major milestones in a Germany-wide campaign at four different locations in November. In Aachen, Darmstadt, Dresden and Nuremberg, experts from more than 51 partners from business, science and society will present, among other things, visionary packaging development software and IT models for linking multiple players in the plastics packaging industry in a virtual data room for the first time.

The packaging industry in transition

It is well known that packaging is important to protect food in particular from harmful influences and spoilage. Depending on the product, the respective packaging requirements are extremely diverse and complex, and the possible combinations are almost endless: hygiene, freshness, odor protection or protection against damage are just some of the decisive parameters for choosing the right packaging. In addition to functionality, design, customer acceptance and costs must also be considered, as well as the question of environmental compatibility and eco-balance.

The latter is playing an increasingly important role. As plastic packaging is notoriously difficult to break down, it is all the more important to recycle it and keep it in the cycle. This is also required by a new EU regulation, which stipulates that all plastic packaging must be made from a minimum of 35% recycled materials by 2030. This is where the research of the AI application hub comes in, which is divided into two innovation labs: K3I-Cycling and KIOptiPack.

Holistic packaging design thanks to the use of AI

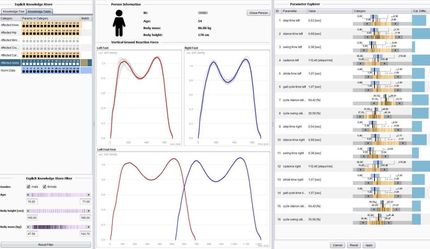

As part of the KIOptiPack innovation lab, the scientists, together with the partners and companies involved, have set themselves the task of developing completely new, cross-industry software that can take into account a whole range of the above-mentioned requirements for plastic packaging and combine them into an overall view with the help of mathematical models and AI-based methods. Once all the data has been fully integrated, the software will suggest the best possible packaging designs for a specific product while minimizing the use of materials. Leading players from all areas of the packaging industry are currently putting together existing software modules that take into account a wide range of factors, such as the shelf life of the product, the life cycle assessment of packaging, its impact on the environment, the use of recyclates and even consumer acceptance. For the first time, this enables companies to arrive at an optimal packaging solution in terms of sustainability without time-consuming test phases and additional use of materials.

"Imagine the innovative software as a personal navigation system for packaging production. Just as a navigation device analyzes different routes and suggests the best route, this software bundles all relevant factors and offers recommendations for optimization," explains Dr.-Malte Schön, KIOptiPack project manager at the Institute of Plastics Processing (IKV) at RWTH Aachen University.

The AI hub experts recently used the existing software elements in a study on meat packaging and its environmental impact to demonstrate in advance that, contrary to all expectations, the answer to greater sustainability in this type of fresh produce does not necessarily lie in reducing the amount of packaging. Less packaging does not automatically lead to less environmental impact - if the reduction in packaging does not result in the required shelf life and the consumer then has to dispose of the food instead of consuming it.

Shared data room for sustainable packaging solutions

Another milestone of the AI application hub is a specially developed electronic system that enables the collection and linking of information from various players in the packaging industry in order to establish more sustainable production processes - in other words, a shared infrastructure and data exchange across factory boundaries. Both will be essential in the future in order to better incorporate recyclates into packaging solutions.

Their sometimes heterogeneous quality poses particular challenges for the industry because it is often not clear what components the recyclates actually consist of or how many and which impurities they may still contain - from recyclate manufacturers to companies that produce packaging films to the food industry, a systematic exchange of data and a standardized terminology will therefore be needed in the future.

"In order to make this exchange meaningful, we first had to develop a completely new ontology, i.e. data language, for the entire industry. A kind of 'dictionary' for all players in the value chain," explains Prof. Dr. Christoph Quix from the Fraunhofer Institute for Applied Information Technology FIT. "Individual data records can thus be assigned to specific and generally valid generic categories and designations and made accessible and usable for everyone."

At the Fraunhofer Institute for Process Engineering and Packaging IVV in Dresden, an IT linking model for a planned data exchange based on the created categories will also be presented for the first time as part of the Open Hub Days. This shows how a wide variety of players and companies and their information can be connected via a kind of secure data highway. The data itself remains protected on the computers of the individual players - so no one has to disclose sensitive information to potential competitors. This also allows conclusions to be drawn about the material behavior of packaging, which in turn enables faster and better material developments.

"As researchers, we are delighted to be able to make a contribution to the transformation towards more sustainable packaging solutions based on secure data with our developments," says Prof. Marek Hauptmann, project manager of the KIOptiPack application at the Fraunhofer Institute for Process Engineering and Packaging IVV. "In the next step, we want to launch similar research projects for the paper industry."

Note: This article has been translated using a computer system without human intervention. LUMITOS offers these automatic translations to present a wider range of current news. Since this article has been translated with automatic translation, it is possible that it contains errors in vocabulary, syntax or grammar. The original article in German can be found here.