Mettler-Toledo

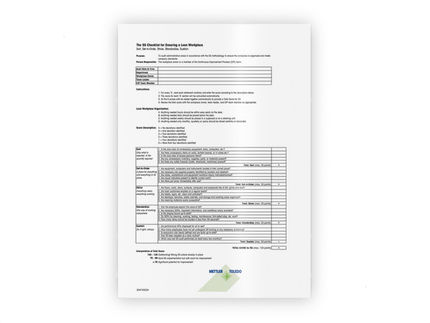

5S audit checklist – Requirements to sustain a lean laboratory

Maintain continuous improvement in laboratory efficiency with the 5s audit checklist

As a lean management method, 5S is a system for workplace optimization, which uses a five-step method to organize and maintain workplaces, systems, and processes. The five Japanese terms represent: sort (Seiri); set in order (Seiton); shine (Seiso); standardize (Seiketsu); and sustain (Shitsuke). The aim is to remove anything that is unnecessary and to eliminate waste. A 5S program delivers improvements in profitability, efficiency, service and safety. It is a good place to start when introducing a lean laboratory approach.

This 5S audit checklist provides a structured way to audit your laboratory 5S program. This simple template guides you through assessment of your laboratory, according to the 5S principles. Using a series of questions, the form generates a maximum overall score of 125. A lab scoring below 75 shows significant potential for improvement in their lean lab approach.

Perform regular audits using the laboratory 5S audit checklist in order to sustain a 5S program, as part of a continuous improvement process (CIP).

Advertisement