New catalyst developed for sustainable propylene production from biomass

Propylene production harnesses biodiesel waste byproduct

Advertisement

Achieving carbon neutrality requires the effective use of renewable biomass. In the production of biodiesel, for instance, glycerol is generated as a major byproduct. Researchers at Osaka Metropolitan University have developed a new catalyst that efficiently converts a derivative of glycerol into bio-based propylene, contributing to sustainable chemical production.

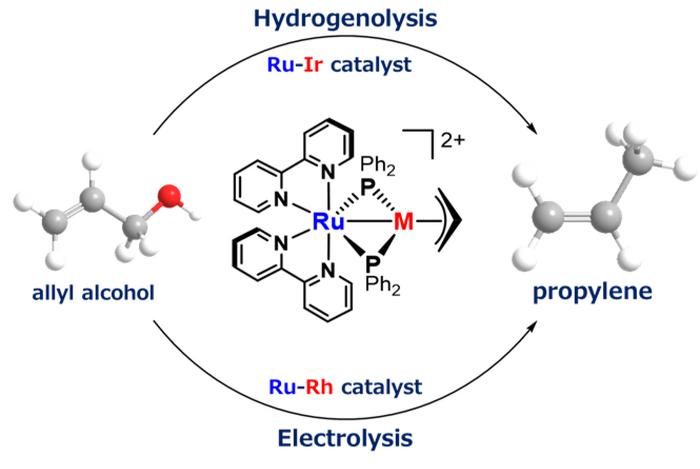

A new catalyst can selectively reduce allyl alcohol, leading to a bio-based propylene.

Osaka Metropolitan University

Propylene is typically produced from petroleum and is widely used in the manufacture of plastics, such as automobile bumpers and food containers. The research team, led by Associate Professor Shin Takemoto and Professor Hiroyuki Matsuzaka from the Graduate School of Science, developed a catalyst that selectively breaks down the oxygen-carbon bond in allyl alcohol, a derivative of glycerol, to produce bio-based propylene.

The newly developed catalyst enables the selective reduction of allyl alcohol to propylene with high efficiency, using renewable energy sources such as hydrogen or electricity. The catalyst contains a special molecule known as a metalloligand, which is designed to facilitate the reversible binding of two metals within the catalyst. This feature enhances the reaction’s efficiency, provides high selectivity, and minimizes the formation of byproducts.

“Our research offers a sustainable alternative to conventional propylene production methods and can contribute to the development of an environmentally friendly chemical industry,” said Professor Takemoto. “We look forward to further advancing this technology and exploring its broader applications.”