Environmentally friendly alternative to PFAS-based coatings

The Leibniz Institute for Plasma Science and Technology (INP) in Greifswald, Germany has developed a new method for the production of ultra-hydrophobic organosilicon polymer coatings. These coatings are an alternative to per- and polyfluorinated compounds (PFAS), which are still used in many industrial applications and sectors.

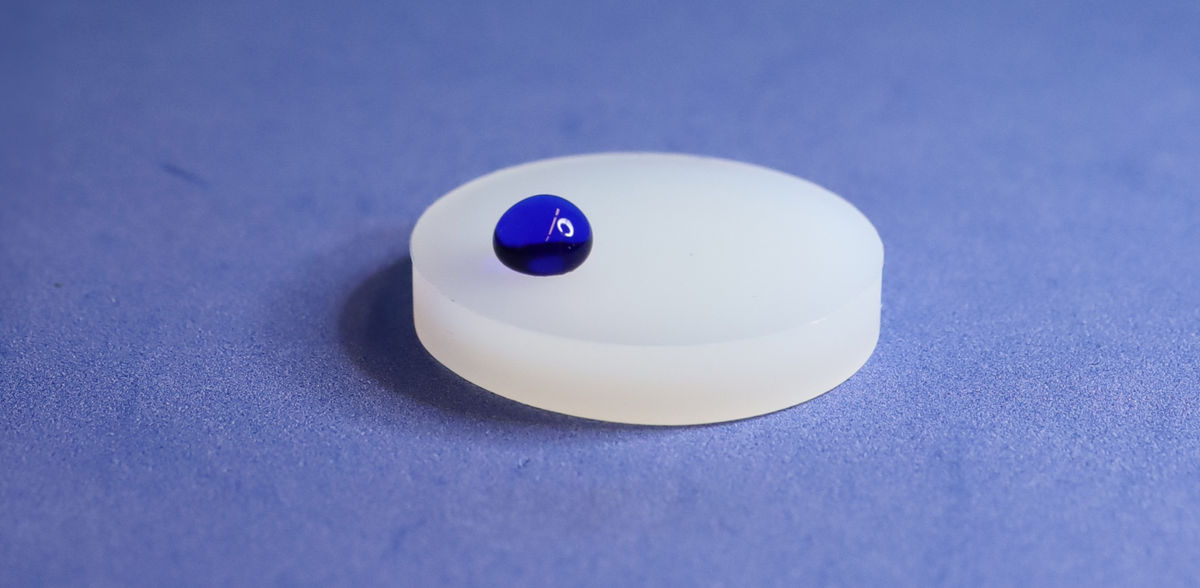

For comparison: a plastic substrate that has not been treated and is therefore not water-repellent.

INP

PFAS compounds have been used for decades to enhance a wide range of products, including those in the medical, semiconductor and textile industries. They are extremely water-repellent and therefore have a number of advantages, such as good non-stick properties and high chemical resistance. However, due to their high stability, PFAS compounds can accumulate in the environment and in living organisms, which is why they are also known as "eternal chemicals". They are therefore considered harmful to the environment and human health and have been banned in some applications in the EU since 2006.

All perfluorinated and polyfluorinated compounds are expected to be included in the global ban list of the Stockholm Convention by 2025 at the latest. This poses an enormous challenge to future high-tech industries such as medical and semiconductor, which rely on these established ultra-hydrophobic coatings.

The organosilicon polymer coating recently developed by INP is based on plasma technology and is a promising and environmentally friendly alternative to PFAS-containing coatings. It is mechanically and chemically stable, up to 200 nm thick and opaque, storable, washable and reproducible. The coatings can be applied to many materials, including metals, plastics and semiconductors.

These properties, together with the fact that they can be applied to thermolabile plastics, make organosilicon polymer coatings ideal for medical device finishing. For example, it can be used in the manufacture or surface modification of implantable devices such as pacemakers or artificial joints.

The INP is currently working on transferring the low-pressure process for depositing the organosilicon polymer layer to a normal pressure process. Concepts for scaling up the technology are also being developed.

"We are very pleased with the results of our research," says Dr Frank Hempel, Head of the Plasma Surface Technology Department at INP. "The organosilicon polymer layer is a promising alternative to PFAS-containing layers and offers a wide range of possibilities for applications in various industrial sectors."

Most read news

Topics

Organizations

Other news from the department science

These products might interest you

OCA 200 by DataPhysics

Using contact angle meter to comprehensively characterise wetting behaviour, solids, and liquids

With its intuitive software and as a modular system, the OCA 200 answers to all customers’ needs

Tailor-made products for specific applications by IPC Process Center

Granulates and pellets - we develop and manufacture the perfect solution for you

Agglomeration of powders, pelletising of powders and fluids, coating with melts and polymers

Dursan by SilcoTek

Innovative coating revolutionizes LC analysis

Stainless steel components with the performance of PEEK - inert, robust and cost-effective

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.