Circuit boards from renewable raw materials

Can ecologically sustainable circuit boards for the electronics industry be produced from cellulose fibers?

Empa researcher Thomas Geiger looked into this question. He is now part of a multinational EU project called "Hypelignum". Its goal: biodegradable electronics.

Biowaste: Experimental board after composting

Empa

For many years, Thomas Geiger has been conducting research in the field of cellulose fibrils – fine fibers that can be produced from wood pulp or agricultural waste, for example. Cellulose fibrils hold great potential for sustainable production and the decarbonization of industry: they grow CO2-neutral in nature, burn without residues and are even compostable. They can be used for many purposes, for example as fiber reinforcement in technical rubber products such as pump membranes.

But can cellulose fibrils perhaps also be used to make circuit boards that reduce the ecological footprint of computers? Printed circuit boards (PCBs) in particular are anything but innocent ecologically: They usually consist of glass fibers soaked in expoxy resin. Such a composite material is not recyclable and can so far only be disposed of properly in special pyrolysis plants.

Computer mouse with an ivory look

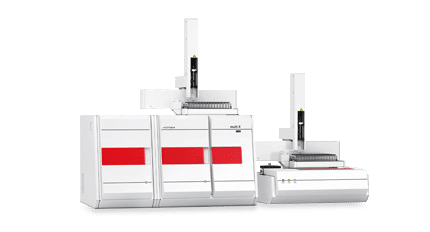

Geiger had already produced circuit boards from cellulose fibrils and investigated their biodegradation. Mixed with water, the bio-fibrils produce a thick sludge that can be dewatered and compacted in a special press. Together with a colleague, he produced 20 experimental boards, which were subjected to various mechanical tests and finally fitted with electronic components. The test succeeded, and the cellulose board released the soldered-on components after a few weeks in natural soil.

Geiger had previously been involved in an Innosuisse project together with the OST University of Applied Sciences in Rapperswil, which produced housing parts for computer mice. The housing parts have a silky sheen and are similar in color and feel to workpieces made of ivory. But no manufacturer could be found who wanted to adopt the method. The price competition for small electronics is still too great for this – and conventional plastic injection molding processes have a clear advantage in this respect.

Circuit boards made of wood wool or cellulose fibers and fibrils

Recently, the opportunity arose to build on existing findings: Empa sustainability specialist Claudia Som was asked if she would like to collaborate on the EU research project Hypelignum. This is led by the Swedish materials research institute RISE and is looking for new ways of sustainably producing electronics. Claudia Som enlisted the help of her colleague Thomas Geiger.

The project started in October 2022, and the research consortium, with participants from Austria, Slovenia, Spain, the Netherlands, Sweden and Switzerland, plans to produce and evaluate eco circuit boards made of various materials: In addition to nanofibrillated cellulose (CNF), wood wool and wood pulp are being investigated as a base; wood veneer is also being used as a base for the circuit boards.

Two Empa labs are collaborating on the project: Firstly, the sustainability specialists led by Claudia Som from the Technology and Society lab. Som will use material databases to calculate the ecological footprint of the eco circuit boards and compare the individual concepts with each other. Thomas Geiger from Empa's Cellulose & Wood Materials laboratory will manufacture the circuit boards from renewable raw materials.

Green electronics has long been a research focus of the lab, which is headed by Gustav Nyström; Nyström's team has already developed various printed electronic components from biodegradable materials, such as batteries and displays. The requirements for industrially produced computer circuit boards, however, are not trivial: Not only must the boards have high mechanical strength, they must also not swell in humid conditions or form cracks at very low humidity.

"Cellulose fibers can be a very good alternative to glass fiber composites," Geiger explains. "We dewater the material in a special press with 150 tons of pressure. Then the cellulose fibrils stick together on their own without any additives. We call this 'hornification'." The key here is at what pressure, temperature and for how long the pressing process must take place to produce optimal results.

Four demonstrators planned

The EU project Hypelignum has ambitious goals: It aims not only to study printed circuit boards made from renewable and compostable raw materials, but also to develop conductive inks for the electrical connections between individual components. These inks are often made based on silver nanoparticles. The researchers are looking for cheaper and less scarce substitute materials, as well as an ecological production method for these nanoparticles.

At the end of the project, four demonstrators ought to show what had been achieved: an ecologically exemplary printed circuit board, a large construction element made of wood that will be equipped with sensors and actuators, pieces of furniture that will be equipped with sensors in an automated production line, and finally a demonstrator that will prove the recyclability of all these components.