Lubricants for Stainless Steel

Chemically functionalized polymer nanoparticles reduce friction on steel surfaces

Mineral oil lubricants protect engine parts from wear, and this effect is enhanced by adding polymer nanoparticles to the lubricating oil. A UK team has now discovered that epoxy functionalization of these nanoparticles further promotes friction reduction on metal surfaces. As the team reports in the journal Angewandte Chemie, nanoparticles containing epoxy groups adhere strongly to stainless steel surfaces, which leads to a significant reduction in friction.

Symbolic image

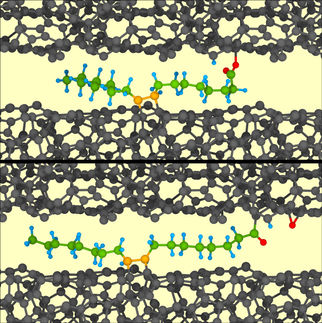

Computer-generated image

(c) Wiley-VCH

Automotive engines comprising well lubricated parts consume less fuel, produce lower emissions, and suffer less long-term wear. Mineral oil is widely used as a lubricant, and nanoparticles can be directly prepared within this solvent using a technique known as polymerization-induced self-assembly. Coating the surface of the metal components with nanoparticles of a few dozen millionths of a millimeter in size protects them from direct contact.

Csilla György and Steve Armes at the University of Sheffield (UK) designed “hairy” nanoparticles comprising oil-soluble poly(lauryl methacrylate) chains and an oil-insoluble nanoparticulate core. These nanoparticles were made to stick strongly to metal surfaces by introducing epoxy groups into the “hairs” by copolymerizing lauryl methacrylate with glycidyl methacrylate, an epoxy-functional monomer.

The team found that the epoxy-bearing nanoparticles reacted with hydroxy groups located at the surface of stainless steel. This reaction led to strong adhesion of the nanoparticles, a phenomenon known as chemical adsorption. Whether chemical adsorption occurred or not depended on the precise location of the epoxy groups. “To our surprise, introducing a far larger number of epoxy groups into the nanoparticle cores had no beneficial effect,” explains Armes.

The adsorbed nanoparticles reduced friction significantly, as the Sheffield team discovered when conducting tribological studies in collaboration with scientists at Lubrizol, an engine oil additives company based in the UK. “Remarkably, the adsorbed nanoparticles remained intact on the stainless steel surface after such experiments, which were conducted at the typical operating temperature of an internal combustion engine,” Armes adds.

Such epoxy-functionalized nanoparticles could therefore mean a further leap in performance for lubricant additives for next-generation engine oil formulations.

Original publication

Other news from the department science

These products might interest you

NANOPHOX CS by Sympatec

Particle size analysis in the nano range: Analyzing high concentrations with ease

Reliable results without time-consuming sample preparation

Eclipse by Wyatt Technology

FFF-MALS system for separation and characterization of macromolecules and nanoparticles

The latest and most innovative FFF system designed for highest usability, robustness and data quality

DynaPro Plate Reader III by Wyatt Technology

Screening of biopharmaceuticals and proteins with high-throughput dynamic light scattering (DLS)

Efficiently characterize your sample quality and stability from lead discovery to quality control

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.