On-site reactors could affordably turn CO₂ into valuable chemicals

“I’m excited by the potential of this technology”

New technology developed at the University of Waterloo could make a significant difference in the fight against climate change by affordably converting harmful carbon dioxide (CO2) into fuels and other valuable chemicals on an industrial scale.

Left: a schematic showing the key components of the reactor and working mechanism. Right: a picture of the CO2 stack, which is a demonstration of the commercial reactors.

Dr. Zhongwei Chen, a chemical engineering professor at the University of Waterloo

Outlined in a study published in the journal Nature Energy, the system yields 10 times more carbon monoxide (CO) – which can be used to make ethanol, methane and other desirable substances – than existing, small-scale technologies now limited to testing in laboratories.

Its individual cells can also be stacked to form reactors of any size, making the technology a customizable, economically viable solution that could be installed right on site, for example, at factories with CO2 emissions.

“This is a critical bridge to connect CO2 lab technology to industrial applications,” said Dr. Zhongwei Chen, a chemical engineering professor at Waterloo. “Without it, it is very difficult for materials-based technologies to be used commercially because they are just too expensive.”

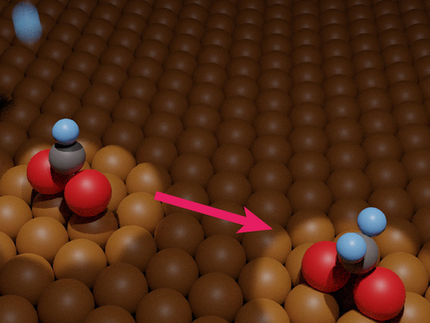

The system features devices known as electrolyzers that convert CO2, a major greenhouse gas produced by burning fossil fuels, into CO using water and electricity.

Electrolyzers developed by the researchers have new electrodes and a new kind of liquid-based electrolyte, which is saturated with CO2 and flowed through the devices for conversion into CO via an electrochemical reaction.

Their electrolyzers are essentially 10-centimetre by 10-centimetre cells, many times larger than existing devices, that can be stacked and configured in reactors of any size.

“This is a completely new model for a CO2 reactor,” said Chen, the Canada Research Chair in Advanced Materials for Clean Energy. “It makes the whole process economically viable for industrialization and can be customized to meet specific requirements.”

The researchers envision on-site reactors at coal-fired power plants and factories, perhaps the size of a house or more, that would be directly fed CO2 emissions, further reducing costs by eliminating the need to capture and collect CO2 first.

They are also developing plans to power the reactors with on-site renewable energy sources such as solar panels, contributing to the environmental benefits.

“I’m excited by the potential of this technology,” Chen said. “If we really want to make a difference by reducing emissions, we have to concentrate on reducing costs to make it affordable.”

Chen’s collaborators at Waterloo included postdoctoral fellow Dr. Guobin Wen and chemical engineering professors Dr. Aiping Yu and Dr. Jeff Gostick. Several researchers at the South China Normal University also contributed.

Original publication

Other news from the department science

These products might interest you

Berghof Reaktortechnologie - Hoch- und Niederdruckreaktoren, Druckbehälter und metallfreie Reaktoren by Berghof

Safe high- and low-pressure systems for aggressive media

Corrosion-resistant reactors with PTFE lining - individually configurable

BUCHI MINICLAVE by C3 Prozess- und Analysentechnik

Flexible small reactor systems - acid resistance, visual control and individual customization options for a wide range of applications!

PhotoSyn™ by Uniqsis

Experience the future of photochemistry

Flow reactor with user-friendly control for higher yields and selectivity

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.