Many advanced and proven solutions to replace fossil carbon in chemistry and materials already available

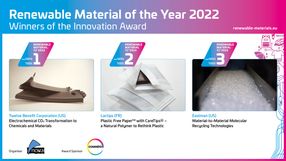

Electrochemical transformation of CO₂, a natural polymer for paper and cardboard coating and material-to-material molecular recycling of plastic waste are the winners of the innovation award “Renewable Material of the Year 2022”

The "renewable materials Conference 2022", 10-12 May in Cologne (Germany), attracted over 400 participants who came to see the latest developments in bio- and CO₂-based chemicals, plastics and other materials as well as advanced recycling technologies in search of non-fossil solutions. 60 speakers and 25 exhibitors from leading companies presented their innovative products and strategies. Over 400 questions were posted by the participants for 14 panel discussions, which were ranked by 1600 likes. The entire conference offered excellent networking opportunities, including coffee and lunch breaks, a dinner buffet and a meeting point in a local brewery.

RMC 2022 Award Winners Stage

nova-Institut GmbH

RMC 2022 Award Winners Collage

nova-Institut GmbH

One participant summed up the motto of the event as follows: “it was a bull's eye that set the course for the gradual phase-out of fossil resources for chemicals and polymers. The decision to expand the profile of the conference to the entire spectrum of renewable materials has proven to be perfect.” The cross-sector concept brought many new insights, ideas and inspirations. And all these different strategies aim to achieve the same goal: replacing fossil carbon with renewable carbon to protect the climate, create sustainable carbon cycles and end dependence on fossil imports with valid new business options.

Renewable material solutions are now available for practically all applications, such as packaging, textiles, consumer goods, toys, automotive and many other technical applications. The latest market data show an impressive increase in all renewable materials:

The production capacities for bio-based polymers, today already over 5 million tonnes, are predicted to grow at an annual rate of 12% until 2026, reaching over 9 million tonnes in 2026 – this growth will mainly take place in Asia. By 2026, their share of the total global polymer production will be 2-3%.

The production capacity of partially CO₂-based polymers has already reached the volume of 1 million tonnes, but the CO₂-based carbon content is only 5 to 11% so far. Currently, considerable investments are being made in CO₂-based ethanol and methanol, which can be used for both fuels and chemicals, especially in Europe.

Large investments are also being made in the area of "advanced recycling", above all a planned investment of 1 billion € in a methanolysis-based project in France for 160,000 tonnes/year of hard-to-recycle plastic waste. Even if the political framework lacks suitable regulations for advanced recycling, the companies assume that the ambitious plans for recycling quotas (e.g. for packaging of 55%) cannot be achieved without chemical recycling.

Alongside polymers and plastics, the market for fine chemicals is also gaining momentum. Products and processes based on renewable carbon are getting closer to the market. Successful innovative solutions meet the increasing consumer demand for sustainability as well as cost-performance. Besides drop-in solutions, completely new products with novel functionalities are entering the market. The presented examples covered a wide range of feedstocks, process technologies and target markets, such as surfactants, dyes, food preservatives and perfumes.

To meet the expected further growth of the conference and exhibition, the conference will move next year, 23-25 May, to Siegburg (Germany), located between Cologne and Bonn, easy to reach by plane and high-speed trains.

Renewable Material of the Year 2022

The innovation award “Renewable Material of the Year” was granted for the second time, after it was first introduced at the Renewable Material Conference 2021. This year nova-Institute received 31 applications, from which a jury of advisory board members and nova experts nominated the six most promising candidates. After short presentations, the participants voted for the three winners: Twelve Benefit Corporation (US) developed an electrochemical device to transform CO₂ into carbon monoxide (CO), a key chemical building-block for many applications. Lactips (FR) presented the Plastic Free PaperTM with a 100% natural, bio-based coating solution for paper and board, with improved barrier properties and enabled thermal sealing without compromising the recyclability of paper. Eastman (US) developed a material-to-material molecular recycling for plastic waste as a feedstock to make new plastics, keeping the carbon in the loop and leaving more fossil feedstocks in the ground.

The innovation award was organized by nova-Institute and sponsored by Covestro (DE).

Here the three winners in detail:

1st Winner: Twelve Benefit Corporation (US): Electrochemical CO₂ Transformation to Chemicals and Materials

Twelve has developed a novel device that uses water and renewable energy to turn carbon dioxide (CO₂) into essential chemicals, materials, and fuels, using a new class of CO₂-reducing catalysts. Twelve is scaling to industrial systems to transform CO₂ into carbon monoxide (CO), a key chemical building block for products including car parts, furniture, building materials, jet fuel, and numerous other materials that are currently made from petroleum. By replacing the fossil carbon in chemicals with renewable, recycled carbon from CO₂, we can eliminate emissions from thousands of essential products. The first products are car parts (with Daimler), sunglasses (with Pangaia), and laundry detergent (with P&G).

2nd Winner: Lactips (FR): Plastic Free PaperTM with CareTips® – a Natural Polymer to Rethink Plastic

Lactips manufactures CareTips®, a natural polymer with multiple technical and performance properties that is biodegradable in various environments and supports manufacturers in their environmental and regulatory transformation. A natural polymer that offers solutions to rethink plastic and master its end of life. It is a unique solution that meets the requirements of the most stringent regulations for single-use plastics. The latest application of CareTips® is Plastic Free PaperTM, a 100 % bio-based coating solution for paper and board that improves barrier properties and enables thermosealing without compromising the recyclability of paper.

3rd Winner: Eastman (US): Material-to-Material Molecular Recycling Technologies

Material-to-material molecular recycling uses plastic waste as a feedstock to make new plastics, keeping the carbon in play and leaving more fossil feedstocks in the ground. The process breaks down the waste to the molecular level – which is indistinguishable from virgin feedstocks – to make new materials. These materials can be recycled over and over without degradation of quality, and is available at-scale, today. These processes are also key to Eastman’s climate strategy, reducing the company’s greenhouse gas emissions by 20-50% in producing the building blocks for new materials, when compared to traditional processes.

Other news from the department business & finance

These products might interest you

Most read news

More news from our other portals

Something is happening in the chemical industry ...

This is what true pioneering spirit looks like: Plenty of innovative start-ups are bringing fresh ideas, lifeblood and entrepreneurial spirit to change tomorrow's world for the better. Immerse yourself in the world of these young companies and take the opportunity to get in touch with the founders.