Lithium-Sulfur batteries: First multimodal analysis in pouch cell format

Evaluation shows how the electrolyte affects the formation of unwanted sulphur particles and polysulphides

Lithium-sulphur (Li/S) batteries have significantly higher energy densities than conventional lithium-ion batteries, but age very quickly. Now, for the first time, a team at HZB has investigated Li/S batteries in the industry-relevant pouch cell format with different electrolytes during operation. Teams from TU Dresden and the Fraunhofer IWS were also involved in the study. With a specially developed measuring cell, impedance, temperature and pressure can be recorded at different times and combined with radiographic images. The evaluation shows how the electrolyte affects the formation of unwanted sulphur particles and polysulphides. The study has been published in the journal Advanced Energy Materials.

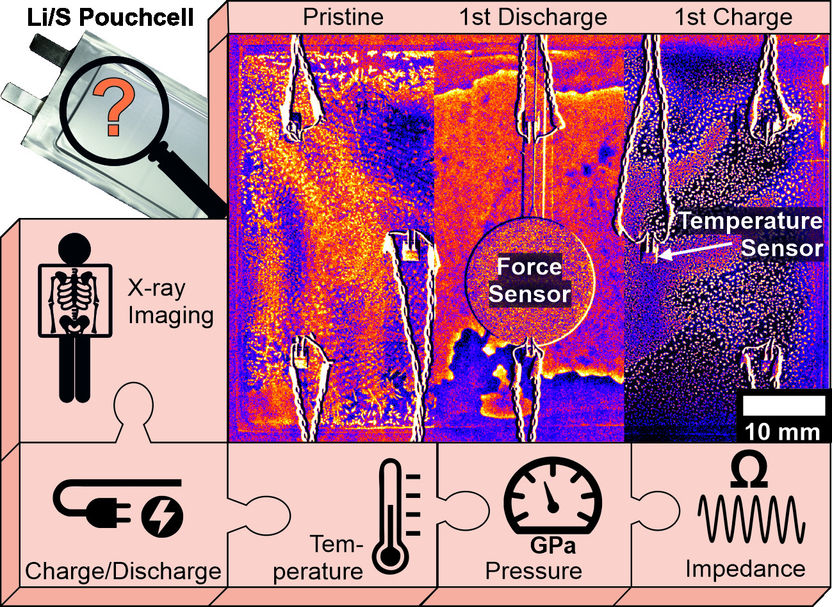

The radiographies of the cell before (left) and after the first discharge (centre) as well as after the first recharge (right). The accumulation of Sulphur-containing particles (bright spots) is visible. This combination of methods allows to compare pouch cells with different electrolytes and additives.

© R. Müller, S. Risse / HZB

Lithium-sulphur (Li/S) batteries theoretically have an energy density of 2500 watt-hours/kg, which is significantly higher than in conventional lithium-ion batteries. In addition, Li/S batteries use more environmentally friendly cathode materials compared to lithium-ion batteries. But there is a problem with Li/S batteries: with increasing number of charging cycles, the active material changes, the metallic lithium anode corrodes, the capacity decreases rapidly. With innovative electrolytes and refined additives, attempts are being made to slow down this ageing. So far, however, mainly Li/S batteries in coin cell design have been investigated, where these reactions take place soaked in plenty of electrolyte.

Format matters

For industry, however, other formats such as round cells (Tesla), prismatic cells (BMW Group) or pouch cells (Volkswagen) are of particular interest. In these formats, the amount of electrolyte is extremely small, which enables particularly high energy densities. At HZB, multimodal operando investigations on Li/S pouch cells have now been carried out for the first time as part of the BMBF-funded project "HiPoLiS". In collaboration with teams from the TU Dresden as well as the Fraunhofer IWS, a team led by Dr. Sebastian Risse investigated single-layer Li/S cells with different electrolytes. "We first need to understand the processes in monolayer cells before we can also optimise multiple layers in pouch cells," Risse is convinced.

Radiography and sensors combined

For their study, they combined measurement data with X-ray radiography analyses, which were created in close cooperation with the group led by HZB imaging expert Dr. Ingo Manke. "This allowed us to draw conclusions about the formation and deposition of sulphur particles and polysulphides over the course of the charging cycles," says Dr Rafael Müller, a postdoctoral researcher in Risse's electrochemistry group. Their results also allowed to evaluate the influence of the electrolyte on particle formation.

The multimodal measuring cell, which Müller developed together with Risse, contains various sensors: they record the electrochemical impedance, the temperature, but also mechanical forces on the electrodes. In addition, the pouch cell is illuminated with X-rays during the entire discharging/charging cycle (operando) this creating several radiographies from which the chemical deposition processes can be deduced.

The pouch cell laboratory at HZB

In order to make further progress on the basis of this cell format, a pouch cell laboratory was set up last year in Prof. Yan Lu's Electrochemical Energy Storage department. To produce these cells, rectangular electrodes in credit card format are stacked on top of each other and - separated only by a thin separator foil - placed in a sealable pocket (pouch). Compared to coin cells, pouch cells require only a small amount of electrolyte to ensure charge transport. All electrochemical processes therefore take place under much drier conditions. "The necessary lack of electrolyte has a very strong effect on these processes and must therefore be investigated directly in an industrially relevant cell format," says Risse.

Energy for the wingcopter

One goal of the HiPoLiS project is to increase the range of a logistics drone of the project partner Wingcopter from Darmstadt with the improved pouch cells from Dresden. For this purpose, the Fraunhofer IWS produces Li/S cells with up to 40 layers, which are then integrated into the existing energy supply of the drone.

Original publication

Rafael Müller, Ingo Manke, André Hilger, Nikolay Kardjilov, Tom Boenke, Florian Reuter, Susanne Dörfler, Thomas Abendroth, Paul Härtel, Holger Althues, Stefan Kaskel, Sebastian Risse; "Operando radiography and multimodal analysis of lithium-sulfur pouch cells – electrolyte dependent morphology evolution at the cathode"; Advanced Energy Materials; 2022

Other news from the department science

Most read news

More news from our other portals

See the theme worlds for related content

Topic World Battery Technology

The topic world Battery Technology combines relevant knowledge in a unique way. Here you will find everything about suppliers and their products, webinars, white papers, catalogs and brochures.

Topic World Battery Technology

The topic world Battery Technology combines relevant knowledge in a unique way. Here you will find everything about suppliers and their products, webinars, white papers, catalogs and brochures.