Load up the hydrogen but hold the carbon

Clean hydrogen from solar power and wood chips

In the global race to curb climate change and reduce carbon emissions, hydrogen is considered a serious contender to replace fossil fuels. Although hydrogen 'burns' cleanly, with only water as a by-product, the current way of making hydrogen a reliable fuel alternative is energy- and carbon-intensive.

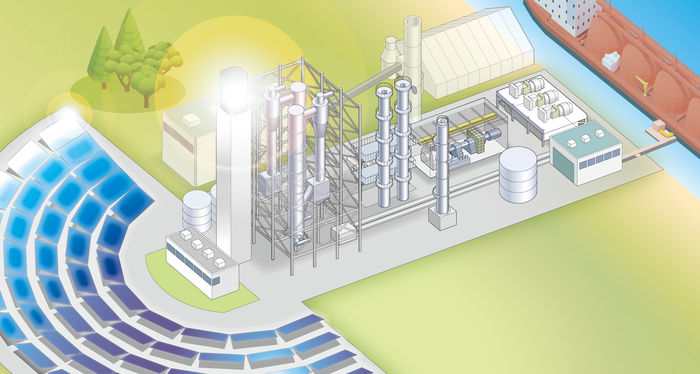

Proposed facility design

KyotoU/Shutaro Takeda

Whether water is split with electricity or hydrogen is released from fossil fuels or other hydrocarbon sources, every step forward in making hydrogen is accompanied by at least two steps back in terms of associated CO2 emissions. In some processes, every kilogram of hydrogen is accompanied by almost 30 kilograms of CO2 output.

Now, a Kyoto University-led team of international researchers has developed a novel hydrogen plant design that draws on fully renewable resources to produce the lowest amount of associated CO2 reported to date. They have published their proposal in the International Journal of Hydrogen Energy.

"Solar energy is the obvious candidate for driving any hydrogen production, but the problem has often been that sunlight is too intermittent," says author Shutaro Takeda.

The team's novel approach of using solar heating to gasify biomass looks to be the most effective and practical way of making hydrogen with a low carbon footprint. They are working on combining two different systems to create a new type of hydrogen facility called the solar-driven advanced biomass indirect-gasification hydrogen production plant, or SABI-Hydrogen plant.

First, to effectively capture sunlight, they chose an arrangement of special mirrors, called heliostats, that focus light onto a receiver at the top of a tower structure. Under these conditions, a heat-transfer material in the receiver can reach temperatures up to 1,000 degrees Celsius.

Next, this heat is transferred from the receiver to the gasifier part of the system, where a vessel containing wood chips as biomass is intensely heated in the absence of oxygen. Rather than burning by combustion, the wood chips are converted to a mixture of gases containing a large proportion of hydrogen.

Alternatively, in the absence of solar heating, this gasifier could also be heated conventionally by burning fuel to deliver heat to the system.

Finally, the team assessed the overall environmental impact of the design, based on an international standard impact assessment method, ReCiPe2016. The result showed that the SABI-Hydrogen system would only emit 1.04 kg of CO2 per kg of hydrogen produced: the smallest value among all existing hydrogen production methods.

Takeda sees nature as our greatest resource and gives us everything we need to combat global warming. "Our modeling shows that using solar power and biomass resources from managed forests could allow us to make hydrogen sustainably and with a low environmental impact," he concludes.

Original publication

Other news from the department science

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.