Superhydrophobic magnetic sponge to help purify water from oil products

Scientists of Tomsk Polytechnic University jointly with the University of Lille (France) have developed a new material capable of purifying water effectively from oil products. It is based on an ordinary household polyurethane sponge. The research team made it superhydrophobic - it repels water, while effectively sorbing oil product molecules.

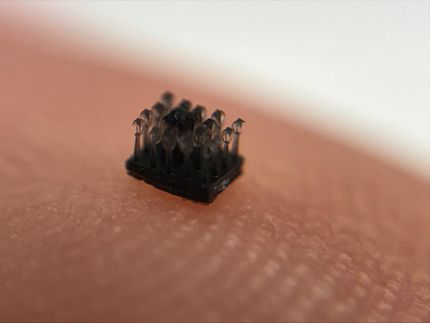

The material samples

TPU

"New oil production methods, especially the ones related to production on the seabed and ocean floor, raise up the risk of spills. We all know about the environmental impact of the accident that happened on a drilling platform in the Gulf of Mexico in 2010. Therefore, one of the most urgent scientific problems is to obtain selective sorbents capable to extract oil products from a water-oil mixture, avoiding interactions with water.

The latter point is crucially important since interactions with water basically result in some resultant products to end up in the water and affect the ecosystem. Furthermore, water saturation drops the sorbent effectiveness. Therefore, we had to find affordable material and make it hydrophobic and efficient for the mentioned goal. We decided in favor of a regular washing sponge," Pavel Postnikov, associate professor at TPU Research School of Chemistry & Applied Biomedical Sciences, says.

Diazonium salts, special organic compounds, were used to make a sponge hydrophobic. The sponge was placed in an aqueous solution with diazonium salts and heated to 60 °C. The resulting active radicals attacked the sponge and formed on the surface new organic groups with hydrophobic properties, being at the same time sensitive to oil products. They act as sorbents that selectively absorb oil molecules.

"The second issue is to find an efficient way to remove this material from water. We chose a magnetic sorbent collection. We added iron nanoparticles in the structure of the sponge, obtained by our original method and characterized by increased susceptibility to nonpolar molecules. We also added hydrophobic organic groups. As a result, we obtained material that almost does not interact with water despite the fact that it is a sponge," the scientist explains.

Petroleum products in water are in the form of an emulsion. This implies that their microscopic droplets are distributed in another liquid, in our case, in the water. According to the researchers, in practice, such emulsions are often highly stabilized. It means they are difficult to separate into individual components.

"We tested our material with both highly stabilized and low stabilized emulsions. The experiments demonstrated that the material is excellent. We also tested its effectiveness on industrial oils that can pollute natural water bodies. The material also showed its high efficiency," Pavel Postnikov says.

Furthermore, the studies showed that the new material can be reused several times. "In experiments, we used it at least five times and there was no drop in its efficiency," the scientist says.

Original publication

Other news from the department science

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.