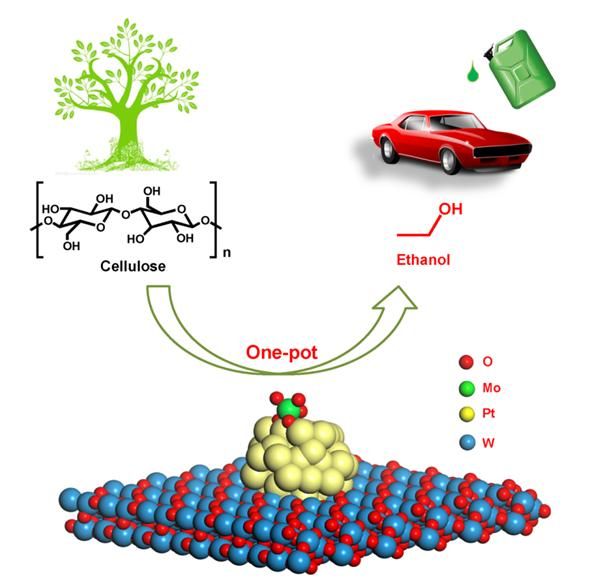

Chemocatalytic approach for one-pot reaction of cellulosic ethanol developed

Scientists at the Dalian Institute of Chemical Physics (DICP) of the Chinese Academy of Sciences have developed a chemocatalytic approach to convert cellulose into ethanol in a one-pot process by using a multifunctional Mo/Pt/WOx catalyst. This approach opens up an alternative avenue for biofuel production.

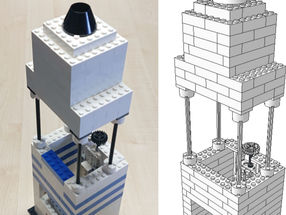

One-pot production of cellulosic ethanol via tandem catalysis over multifunctional Mo/Pt/WOx catalyst.

WANG Aiqin

Cellulosic ethanol is one of the most important biofuels, yet commercial production is hindered by the low efficiency and high cost of the bioconversion process.

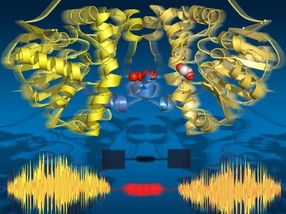

Prof. WANG Aiqin, leader of the research group, and her colleagues developed a chemocatalytic process in which two separate reactions, cellulose conversion to ethylene glycol and ethylene glycol conversion to ethanol, were coupled in a one-pot reaction by using a multifunctional Mo/Pt/WOx catalyst, thus achieving an ethanol yield of higher than 40 %.

While noting that the new process can still be made more efficient, WANG said that "in principle" the new process can "overcome the intrinsic limitations on ethanol concentration imposed by the bioconversion process."

"With further improvement in catalyst efficiency and robustness, this one-pot chemocatalytic approach shows great potential in the practical production of cellulosic ethanol in the future," WANG said.

Original publication

Other news from the department science

These products might interest you

Berghof - Reactor Controller by Berghof

High-performance heating system: Precision for small reactors up to 300 ml

Discover auto-tuning, intelligent stirring and air cooling for precise process control

Berghof Reaktortechnologie - Hoch- und Niederdruckreaktoren, Druckbehälter und metallfreie Reaktoren by Berghof

Safe high- and low-pressure systems for aggressive media

Corrosion-resistant reactors with PTFE lining - individually configurable

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.