Breakthrough in acidic water electrolysis via ruthenium-based catalysts

hydrogen fuel, with the advantages of clean, renewable and of high fuel efficiency, is seen as the "ultimate fuel" and getting more attention around the world. water electrolysis is an ideal way to produce hydrogen, yet it requires active and stable catalysts which make this process more efficient and cheaper. Without suitable catalysts, turning water into fuel only seems too good to be true.

Oxygen evolution reaction (OER) and oxygen reduction reaction (ORR) can be regarded as two trophies in the field of efficient utilization of hydrogen energy. However, in acidic OER, high applied potential was needed and the stability of the catalyst is very poor, which resulted in the slow kinetics. With Ru catalyst, the process is significantly accelerated.

CUI Jie

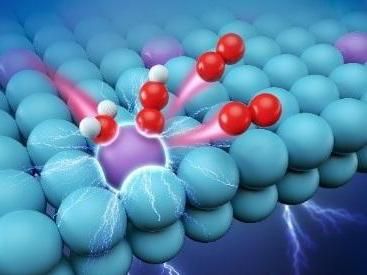

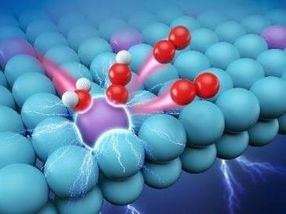

Ru was atomically dispersed in metal support. In acidic electrolyte environment, water molecules was adsorbed on the active site Ru atom under the applied potential, and then single atom Ru catalyst boosts acidic water electrolysis producing oxygen via OOH mechanism. (Purple, blue, red and white balls represents Ru, Pt, O and H atoms, respectively.)

WU Yuen

Fortunately, a recent study is bringing this dream closer. Professor WU Yuen's team from the University of Science and Technology of China (USTC) successfully prepared a kind of Ruthenium single atom alloy catalyst, which greatly accelerates the process of water eletrolysis with lower overpotential (220 mV).

The group successfully prepared a single atom Ruthenium (Ru) catalyst by surface defect engineering to capture and stabilize single atoms. The single atom Ru catalyst delivers a 90 mV lower overpotential to reach a current density of 10 mA/cm2, and an order of magnitude with a longer lifetime than that of commercial RuO2.

In this study, researchers constructed a series of alloy-supported Ru1 using different PtCu alloys through sequential acid etching and electrochemical leaching. They also found a volcano relation between oxygen evolution reaction (OER) activity and the lattice constant of the PtCu alloys. Density functional theory investigations reveal that the compressive strain of the Pt-skin shell engineers the electronic structure of the Ru1, allowing optimized binding of oxygen species and better resistance to over-oxidation and dissolution.

Compared with Iridium-based systems, which have better dissolution resistance, Ru-based ones have more abundant reserves and have been evaluated to be a more active OER catalyst due to its lower overpotential.

This research makes hydrogen production through water electrolysis easier and more efficient, and allows people to see the great potential of hydrogen as an alternative new energy in the future.

Nevertheless, till now, the stability problem of catalyst hasn't been completely resolved. "There are still many explorations left to further improve the reaction system and we are going to continue designing experiments and trying to find the best way to boost activity and stability of catalysts." said Ph.D. YAO.

Original publication

Other news from the department science

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.