thyssenkrupp commissions first commercial bioplastics plant in China

Production capacities for bioplastics expected to grow

To reduce reliance on petroleum-based plastics, thyssenkrupp has developed a manufacturing process for the bioplastic polylactide (PLA). The world’s first commercial plant based on the patented PLAneo® technology recently started production in Changchun, China. It is operated by the Jilin COFCO Biomaterial Corporation, a subsidiary of COFCO, China’s largest food and beverage group. The new plant produces all standard PLA types, among other things for the production of eco-friendly packaging, fibers, textiles and engineering plastics.

The COFCO bioplastics plant with the PLA (polylactide) technology from thyssenkrupp's polymer specialists Uhde Inventa-Fischer

thyssenkrupp Industrial Solutions AG

Sami Pelkonen, CEO of the Electrolysis & Polymers Technologies business unit of thyssenkrupp Industrial Solutions: “The bioplastics market will continue to grow in the coming years, not least due to the increasing environmental awareness of industry, governments and consumers. With our PLAneo® technology we want to do our bit to make the plastics sector more sustainable and resource-friendly. With it we enable our customers to produce high-quality bioplastics with a wide range of properties – at a price that is competitive with conventional plastics.”

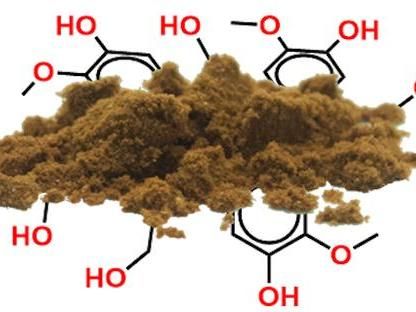

Polyactide (PLA) is a 100% bio-based and compostable plastic which thanks to its physical and mechanical properties can replace conventional oil-based polymers in many areas. The starting material for PLA production is lactic acid, which is recovered from renewable resources such as sugar, starch or cellulose.

PLAneo® technology converts lactic acid into PLA in a particularly efficient and resource-friendly way. Another advantage is its transferability to large-scale plants with capacities of up to 100,000 tons per year. In developing the technology, thyssenkrupp’s subsidiary Uhde Inventa-Fischer profited from decades of expertise gained from the construction of more than 400 polymerization plants and extensive experience in the scale-up of new technologies. For the new plant in Changchun thyssenkrupp provided the engineering, key plant components and supervision of construction and commissioning.

Most read news

Topics

Organizations

Other news from the department business & finance

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

Last viewed contents

Improving the safety of lithium-ion batteries in electric vehicles - Better understanding of the problems associated to the thermal runaway of lithium-ion batteries

Twisting laser light offers the chance to probe the nano-scale - New method to sensitively measure the structure of molecules

Analytica Vietnam continues to grow in terms of exhibitors, space and visitors