Cognis Mexico: new sulfation facility improves quality, increases capacity

Cognis has opened a new SO3 Sulfation plant at its site in Ecatepec, Mexico. The company invested in a state-of-the-art facility, which produces ingredients for use in products such as shampoos, shower gels, paints, paper coatings, and agrochemical applications. By increasing both the plant’s capacity and the quality of its products, this investment will enable Cognis to target new markets in the region. The Ecatepec site near Mexico City is now better than ever equipped with all important technologies like sulfation, Ethoxylation and multi-purpose reactors in close proximity of major customers.

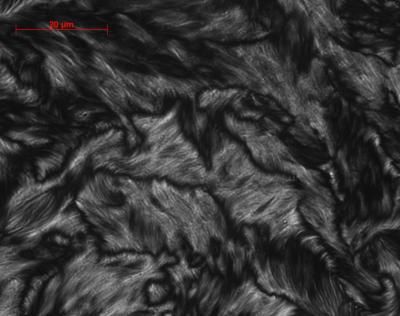

Products from the new sulfation unit, such as fatty alcohol sulfates, fatty alcohol ether sulfates and other surface active agents have significantly better quality. The new reactor uses crystalline sulfur instead of chlorosulfonic acid as the basis for the sulfation process, and as a result the products are now purer than before, containing no chlorine byproducts. In addition the facility enables Cognis Mexico to provide products into the market with low 1,4-dioxane concentrations matching worldwide benchmarks. The new reactor operates at lower temperatures with the effect that organic components do not discolor and stay more transparent. This makes Ecatepec’s products suitable for crystal clear formulations, which meets an important market demand. Improved product quality also provides enhanced performance in emulsion polymers for coatings and adhesives.

As well as increasing product quality, the progress in sulfation technology also makes possible higher throughput rates, which eventually will increase the plant’s overall capacity. Says Roland Spörer, site manager and Director Care Chemicals and Supply Chain: “This new facility complements our existing plants and sulfation departments in Argentina, Brazil and the USA perfectly, and enables us to cover the entire North, Central and South American surfactants market.” He was also very impressed by the speed with which the unit was built. “We applied for the construction permit in August 2008,” he says. “It was granted very quickly, and the actual construction phase took just seven months – that seems almost like a record for this kind of project.”

Most read news

Other news from the department manufacturing

These products might interest you

OCA 200 by DataPhysics

Using contact angle meter to comprehensively characterise wetting behaviour, solids, and liquids

With its intuitive software and as a modular system, the OCA 200 answers to all customers’ needs

Tailor-made products for specific applications by IPC Process Center

Granulates and pellets - we develop and manufacture the perfect solution for you

Agglomeration of powders, pelletising of powders and fluids, coating with melts and polymers

Dursan by SilcoTek

Innovative coating revolutionizes LC analysis

Stainless steel components with the performance of PEEK - inert, robust and cost-effective

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.