TA Instruments

How to Ensure Polymer Strength and Durability with Mechanical Testing

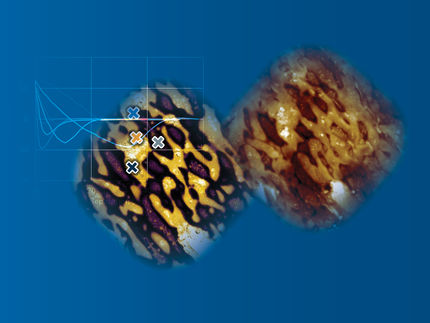

Tensile and Fatigue Testing for Longevity and Reliability of Polymer Materials and Components

Polymer strength and durability testing is essential for demanding applications such as airplanes and construction materials. To develop cutting-edge polymer products, definitive, application-specific characterization is needed to validate material reliability. Leading labs and manufacturers use monotonic and fatigue testing to inform material selection and design, followed by performance assessments.

Monotonic testing involves applying a steady load and measuring the material's response until failure. This measures yield strength, ultimate strength, Young's modulus, and elongation. Fatigue testing applies repeated loads, measuring damage and failure, often used in "Fatigue to Fracture" or "Test to Success" evaluations.

Combined, these tests provide detailed analysis of polymer strength and durability, especially at realistic temperatures. Early testing can reduce costs by identifying weaknesses in material selection and design before reaching costly validation or post-launch phases. Research examples show how instrumentation supports polymer selection, fatigue analysis, and validation.

Advertisement