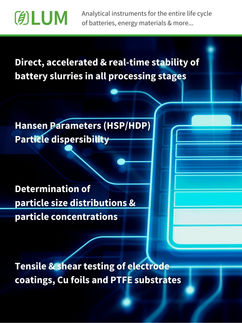

Analyze particles, dispersions and coatings in batteries and energy storage materials

Particle size distribution & dispersibility, separation, adhesive strength of electrode layers

Although active materials for batteries and fuel cells span the entire periodic table, the need for carbon (soot, graphene, carbon nanotubes, etc.) is undisputed. The inherent chemical and physical properties of the raw materials, the interaction between the particle surface and the continuous phase and the dispersing process itself play a role in its dispersibility. All three factors must be considered.

Thanks to STEP technology and the multi-sample concept, the LUM analyzers enable the efficient determination of particle size distributions and particle surface properties according to the Hansen parameter concept.

Manufactured battery pastes are characterized undiluted with regard to their separation stability. The adhesion analyser LUMiFrac is used to determine the adhesion of coatings on copper foils for anodes and aluminum foil coatings for cathodes in lithium-ion batteries.Time savings of up to 80% can be achieved without clamping and with up to 8 samples in parallel.

Download white paper now

Analyze particles, dispersions and coatings in batteries and energy storage materials

Particle size distribution & dispersibility, separation, adhesive strength of electrode layers

Advertisement