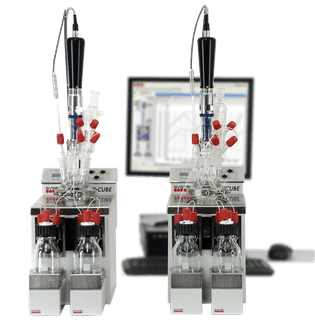

Learn more about how automation has significantly improved production in a hydrogenation lab

Best practice for increased productivity and safety in a hydrogenation lab through process automation

Laboratories are under permanent pressure to validate and optimize new processes and formulations. Production facilities look to the labs to supply them with reliable and thoroughly tested parameters for safe operation. This is the only way to ensure consistently high quality products.

Even when using the very best equipment there is a point when a laboratory can no longer fulfil the ever rising demands. That’s when to decide whether to discharge or to upgrade.

This whitepaper describes the upgrade option, based on the case study on a pharmaceutical manufacturer whose hydrogenation reactors were upgraded with SYSTAG's FlexyConcept. This has vastly improved both productivity and safety.

Download white paper now

Learn more about how automation has significantly improved production in a hydrogenation lab

Best practice for increased productivity and safety in a hydrogenation lab through process automation

White Paper classification

White papers on related topics

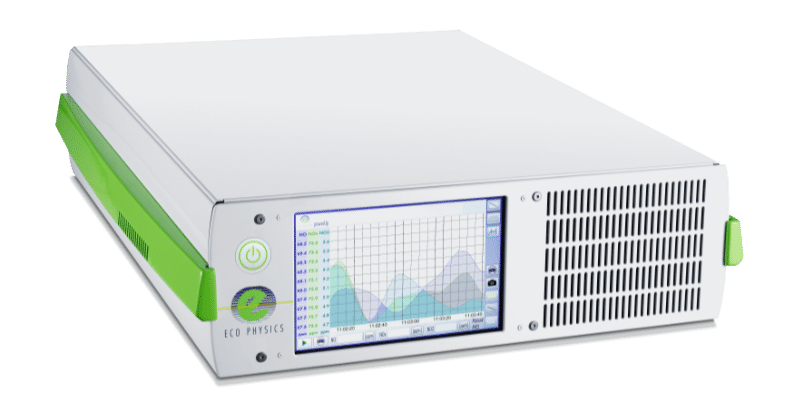

Products on related topics

Manufacturers of similar products

See the theme worlds for related content

Topic world Synthesis

Chemical synthesis is at the heart of modern chemistry and enables the targeted production of molecules with specific properties. By combining starting materials in defined reaction conditions, chemists can create a wide range of compounds, from simple molecules to complex active ingredients.

Topic world Synthesis

Chemical synthesis is at the heart of modern chemistry and enables the targeted production of molecules with specific properties. By combining starting materials in defined reaction conditions, chemists can create a wide range of compounds, from simple molecules to complex active ingredients.