NIR spectrometers at a glance: products, function and application

NIR spectrometers (near-infrared spectrometers) measure the absorption of near-infrared light by samples to analyse their chemical composition, structure or physical properties. This page provides an overview of products from different manufacturers.

Are you looking for general information on the topic? Our guide gives you all the important information on how it works and how to use it.

NIR spectrometers at a glance: products, function and application

NIR spectrometers (near-infrared spectrometers) measure the absorption of near-infrared light by samples to analyse their chemical composition, structure or physical properties. This page provides an overview of products from different manufacturers.

Are you looking for general information on the topic? Our guide gives you all the important information on how it works and how to use it.

NIR spectrometers at a glance

OMNIS NIR Analyzer Liquid/Solid by Metrohm

Ultra-fast, non-destructive analysis of liquids and solids

One device for liquid, solid and viscous samples - without conversion

Automatic detection of the sample ✓ Automated multi-position measurements for reproducible results ✓ Low training requirements thanks to simple operation ✓

2060 The NIR-R Analyzer by Metrohm

Efficient inline analysis for liquids and solids

Versatile NIR analyzer for real-time process control

Fully automated measurements in the process environment ✓ Reduced training time thanks to intuitive user interface ✓ Minimal maintenance thanks to stable fiber optic technology ✓

SEC2020 by C3 Prozess- und Analysentechnik

Flexible spectrometer system for spectro-electrochemical measurements - without optical fibers and with a wide range of applications in the UV/Vis/NIR range

The SEC2020 spectrometer system is perfectly tailored to spectro-electrochemical measurements. With its modular combination of spectrometer and beam s

MPA III by Bruker

Spectroscopy in a New Light: FT-NIR made easy

MPA II - The tailor-made solution for your quality control

Maximum Flexibility: The MPA III is custom-build for you to match your very own application needs ✓ Easy Operation: Even untrained personnel can use the MPA III spectrometer from day one ✓ Green Technology: By saving energy and chemicals, the MPA III can reduce your ecological footprint ✓

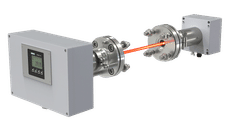

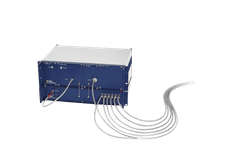

Near Infrared (NIR) spectrometer for process monitoring by Polytec

Shed Light on Your Manufacturing Process: Optimized Quality Control using NIR Spectroscopy

Near-infrared fiber-coupled measurement technology for inline process monitoring

Shed Light on Your Manufacturing Process: Optimized Quality Control using NIR Spectroscopy ✓ Multiplexer for up to 6 fiber-coupled sensors on a single spectrometer ✓ Durable optical components without mechanically moving parts for lower maintenance costs

2060 The NIR Analyzer by Metrohm Prozessanalytik

A turnkey solution for all major industries

Maximized process efficiency by inline monitoring of all key parameters within seconds

Best process suitability due to robust designed and state-of-the-art spectrometer hardware ✓ The embedded process software covers all requirements for a safe and economical PAT ✓ Easy method development by intuitive, easy-to-use software and Metrohm application support ✓

FT-NIR Prozess-Spektrometer MATRIX-F II by Bruker

FT-NIR Process Monitoring: Keeping an eye on your process

Measure key process parameters for real-time reaction monitoring and control

Smart Analyzer with Integrated Process Communication: Fully autonomous with integrated PC ✓ IoT Interface Ready for Industry 4.0: Check your device parameters for condition monitoring ✓ Long Life NIR Source & Laser Diode: Less service interactions and highest precision ✓

Choose NIR spectrometers by product category

Select NIR spectrometers for your application

Buy NIR spectrometers for the lab or the production process

Related product categories

Find more NIR spectrometers content in our topic worlds

Topic World Spectroscopy

Investigation with spectroscopy gives us unique insights into the composition and structure of materials. From UV-Vis spectroscopy to infrared and Raman spectroscopy to fluorescence and atomic absorption spectroscopy, spectroscopy offers us a wide range of analytical techniques to precisely characterize substances. Immerse yourself in the fascinating world of spectroscopy!

Topic World Spectroscopy

Investigation with spectroscopy gives us unique insights into the composition and structure of materials. From UV-Vis spectroscopy to infrared and Raman spectroscopy to fluorescence and atomic absorption spectroscopy, spectroscopy offers us a wide range of analytical techniques to precisely characterize substances. Immerse yourself in the fascinating world of spectroscopy!

NIR spectrometer guide: Everything you need to know, clearly explained

An NIR spectrometer (near-infrared spectrometer) is an analytical device that operates in the near-infrared region of the electromagnetic spectrum to analyse the chemical composition of samples. It uses the interaction of near-infrared radiation (800 to 2500 nm) with molecules to produce characteristic absorption spectra. These spectra provide information about the molecular structure and concentration of various substances in a sample without the need for extensive sample preparation.

Advantages of NIR spectrometers

NIR spectrometers offer a variety of advantages that make them an indispensable tool in research and industry:

- Fast analyses: Measurements can be taken in a few seconds.

- Non-destructive testing: Samples remain intact, which is particularly important for valuable or sensitive materials.

- No chemicals required: Unlike many other analytical methods, NIR spectrometers do not require chemical reagents.

- Versatility: NIR spectrometers can be used to analyse solids, liquids and powders.

- Real-time monitoring: They enable continuous process monitoring and quality assurance in production processes.

Target group and typical applications in various industries

NIR spectrometers are used in a wide range of industries, including the food and beverage industry, pharmaceuticals, chemicals and agriculture. The target group includes scientists, quality assurance officers, engineers and production managers who require precise, fast and reliable analyses.

- Food industry: For determining moisture, fat, protein and other ingredients in products such as cereals, milk and meat.

- Pharmaceutical industry: For the identification and quantification of active ingredients, homogeneity testing and quality control in production.

- Chemical industry: For analysing chemical compositions and reactions, and for monitoring production processes.

- Agriculture: For determining the quality of seeds, feed and soil.

Product overview: NIR spectrometer types

NIR spectrometers come in different varieties, depending on the specific needs of the user. The following are the three main types of NIR spectrometers: portable, laboratory and process NIR spectrometers.

Portable NIR spectrometers

Portable NIR spectrometers are compact and lightweight devices designed for on-site use. They provide fast analysis directly in the field or on the production line and are ideal for applications where mobility and flexibility are crucial.

Advantages:

- Lightweight and portable

- Instant results

- Easy to use, even without extensive technical knowledge

Typical applications:

- Quality control of raw materials in the food industry

- Determining the ripeness and quality of agricultural products

- Mobile analysis in environmental monitoring

Laboratory NIR spectrometers

Laboratory NIR spectrometers offer high precision and advanced analysis options. These devices are indispensable in research institutions and development laboratories, as they enable the detailed examination of complex samples.

Advantages:

- High resolution and precision

- Wide range of analysis options

- Option to analyse solid, liquid and paste-like samples

Typical applications:

- Analysis of active pharmaceutical ingredients and formulations

- Detailed analysis of chemical reactions

- Research and development of new materials

Process NIR spectrometers

Process NIR spectrometers are robust and designed for integration into production lines. They enable continuous real-time monitoring of production processes, which significantly improves quality assurance and process control.

Advantages:

- Real-time monitoring of production processes

- Robust design for industrial use

- Easy integration into existing production plants

Typical applications:

- Monitoring mixing ratios in chemical production

- Quality control in food production

- Monitoring pharmaceutical production processes

Application areas of NIR spectrometers

NIR spectrometers are used in many industries because they provide fast and reliable analysis. Here are some specific applications and real-world success stories:

Food industry

In the food industry, NIR spectrometers are indispensable for quality control and product development. They enable quick determination of moisture, fat, protein and other ingredients, ensuring compliance with quality standards and legal requirements.

Application: Quality control of grain

A leading grain processing company uses NIR spectrometers to monitor protein content and moisture in real time. This has improved the consistency of product quality and reduced the amount of waste, resulting in significant cost savings and increased customer satisfaction.

Case Study: Dairy products

A dairy processing company uses NIR spectrometers to control the fat and protein content in milk and cheese products. The precise and rapid analyses enable immediate adjustment of the production process to ensure consistently high product quality.

Pharmaceutical industry

In the pharmaceutical industry, NIR spectrometers are crucial for quality control and process optimisation. They enable the rapid identification and quantification of active ingredients, as well as the monitoring of the mixing ratios and homogeneity of tablets and capsules.

Application: Monitoring the concentration of active ingredients

A pharmaceutical company uses NIR spectrometers to monitor the concentration of active ingredients in tablets during production. Real-time analysis has reduced production time and increased efficiency. At the same time, product quality has improved because deviations can be detected and corrected immediately.

Case Study: In-line monitoring

Another example is the in-line monitoring of mixing processes in pharmaceutical production. Here, NIR spectrometers enable continuous monitoring and control of the mixing process, ensuring a consistent distribution of active ingredients.

Chemical industry

In the chemical industry, NIR spectrometers are used to analyse chemical reactions and to monitor the production of polymers, paints and varnishes. They help to detect and correct process deviations at an early stage.

Application: Monitoring polymerisation reactions

A chemical company uses NIR spectrometers to monitor polymerisation reactions in real time. This enables changes in chemical composition to be detected immediately and the production process to be adjusted accordingly. This results in higher product quality and a reduction in waste.

Case Study: Paint production

In the paint industry, NIR spectrometers are used to monitor pigment concentration and viscosity in paints. The fast and precise analysis makes it possible to optimally control the production process and ensure the quality of the end products.

Buying guide for NIR spectrometers

When purchasing an NIR spectrometer, several factors need to be considered to ensure that the device meets specific requirements. Here are some decision-making aids that can help you choose the right NIR spectrometer.

Decision-making aids for different needs

- Area of application: Choose a device that is aligned with the specific requirements of your industry. For example, portable NIR spectrometers are ideal for mobile analysis, while process NIR spectrometers are suitable for integration into production lines.

- Accuracy and resolution: For applications that require a high degree of precision, such as in the pharmaceutical industry, a laboratory NIR spectrometer with high resolution is the best choice.

- Mobility and flexibility: If analyses need to be carried out on site, portable NIR spectrometers are the best option.

- Integration into existing systems: When monitoring production processes, it is important that the NIR spectrometer can be seamlessly integrated into existing production facilities.

Tips for choosing the right NIR spectrometer

- Budget planning: Determine your budget in advance and compare different models to find the best value for money.

- Check the specifications: Pay attention to the spectral range, resolution and accuracy of the device. These parameters determine the applications for which the NIR spectrometer is suitable.

- Ease of use: Choose a device that is easy to operate and maintain, especially if it is to be used by multiple people.

- Support and training: Ensure that the manufacturer offers training and technical support to ensure smooth operation.

FAQs about NIR spectrometers

How does an NIR spectrometer work?

An NIR spectrometer sends near-infrared light through a sample and measures how much of that light is absorbed or reflected at different wavelengths. These measurements are converted into a spectrum that describes the chemical composition of the sample.

What samples can be analysed with an NIR spectrometer?

NIR spectrometers can analyse a wide range of samples, including solids, powders, liquids and pastes. They are frequently used in the food, pharmaceutical and chemical industries.

How often does an NIR spectrometer need to be calibrated?

The calibration of an NIR spectrometer depends on the frequency and conditions of use. In general, the device should be regularly calibrated to ensure accurate results. Most manufacturers recommend an annual calibration.

What maintenance is required for an NIR spectrometer?

NIR spectrometers require minimal maintenance. It is important to keep the optical components clean and to regularly check the device to ensure that it is working correctly. Some devices have a self-diagnostic function that notifies users of necessary maintenance.

Can an NIR spectrometer be used to analyse mixtures?

Yes, NIR spectrometers are excellent for analysing complex mixtures. They can determine the concentration of various components in a mixture without the need for extensive sample preparation. This makes them particularly useful in the food and pharmaceutical industries.

Haven't found the right product yet?

The chemeurope.com Product Search

Start your targeted search now with a wide selection of filter options. Here you can easily find the right product for your search, including manufacturer information and options for requesting a quote or downloading the corresponding brochure.