Tailor-made products for specific applications

Product Development and Contract Manufacturing of Granules and Pellets

IPC Process-Center GmbH & Co. KG

Agglomeration of Powders I Pelletization of Powders and Liquids I Coating with Melts and Polymers

Specific changes in their morphology or coating with functional polymers can improve the performance of additives. However, the necessary techniques are not always available in-house. Outsourcing to a contract manufacturer makes product development much easier and shortens the time-to-market, thanks to the immediate availability of the required technology and the contractor’s know-how.

From the clients’ initial idea, IPC’s experienced engineers support the development of a product from feasibility studies through to manufacturing. Samples ranging from a few kilograms up to 100 kg can be produced for application testing, and larger quantities for the market launch or future contract manufacturing of annual requirements. Despite the differences in the nature of the products, IPC makes its technologies and methods available for chemical additives, feed, food additives as well as pharmaceutical excipients. Depending on the requirements, a suitable quality assurance system is put in place for each application.

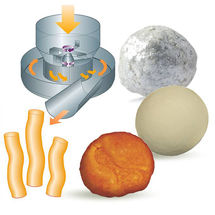

IPC’s core technology is the fluidized bed technique, which - due to its mild processing conditions - is also suitable for sensitive products. The versatility of the fluidized bed technique makes it suitable to create a wide variety of product variants and features, with a selection of methods available for many applications:

- Fluidized bed agglomeration improves both the solubility and the flowability of fine powders. Mixture composition is fixated by agglomerate formation, ensuring constant mixture ratios for subsequent processing steps.

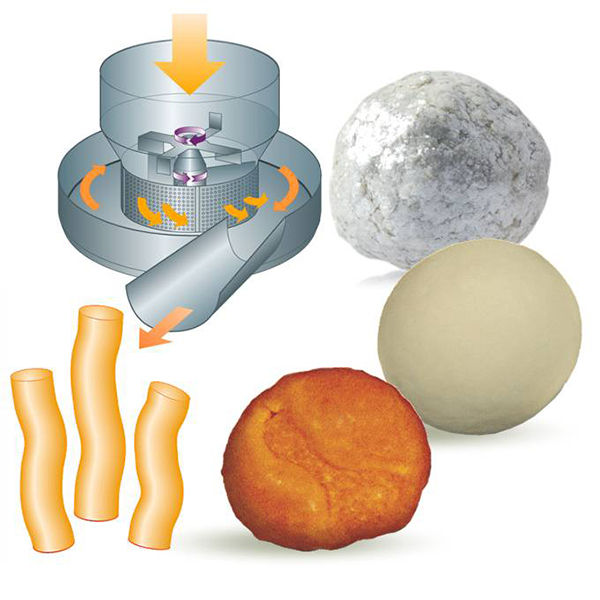

- Pelletization by extrusion and spheronizing creates compact, round matrix pellets from liquid and solid components. Its mild processing conditions allow temperature-sensitive substances to be used as well.

- Coating covers particles with a functional film former that gives the product very specific properties. These range from simple moisture protection to the controlled release of the product in a particular application.

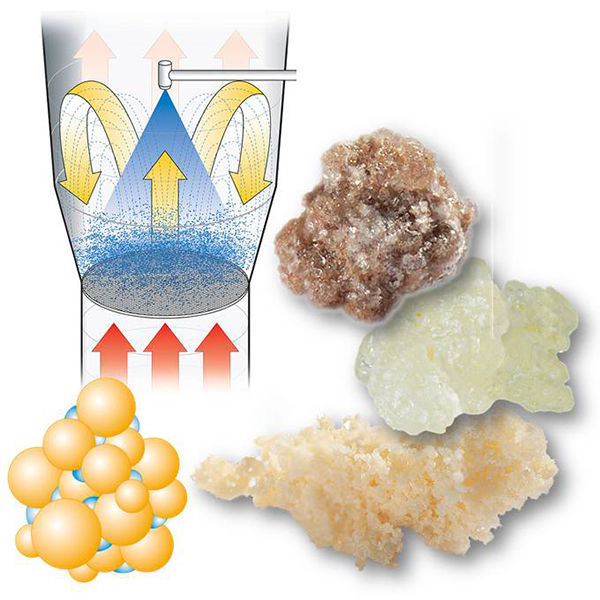

- Spray granulation of liquids enables efficient drying with simultaneous formation of compact granules and pellets. The product’s high abrasion stability avoids dust formation during handling and - due to its compact, regular structure - offers many benefits for subsequent use.

1

Spray granulation drying of liquids to granules and pellets

2

Coating of additives with functional film formers

3

Agglomeration of powders to improve solubility and fixate mixtures

4

Pelletization of powders and liquids into compact, round pellets

Request information about Tailor-made products for specific applications now

Tailor-made products for specific applications

Product Development and Contract Manufacturing of Granules and Pellets