LUMiReader X-Ray

Separation and Sediment Analysis – All Dispersing Agents Are Possible

Characterization of Highly Concentrated Nano- and Microdispersions

LUM GmbH is market leader in innovative analysers for direct and accelerated stability analysis and particle characterization of dispersions. In addition, solutions in the field of material testing are now provided with the new LUMiFrac®.

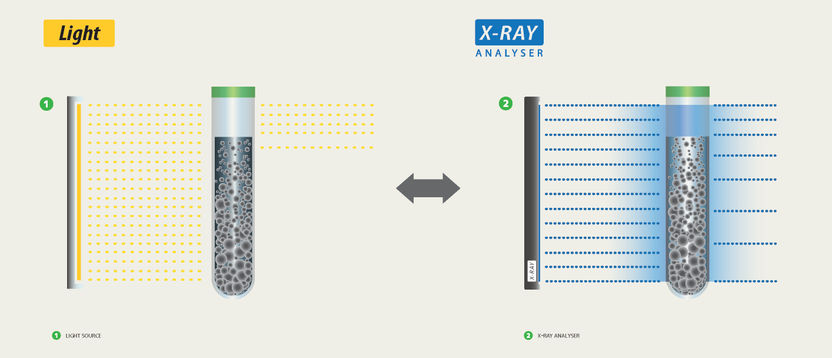

The innovative Separation Analyser LUMiReader® X-Ray extends the proprietary STEP-Technology® to X-radiation, to characterize the separation behaviour of highly concentrated, opaque suspensions and emulsions for a broad range of particle sizes under original conditions (no dilution required).

LUMiReader X-Ray features the advantages:

- Direct and non-contact measurement of samples of highest concentration

- Determination of concentration gradients in nano- and microdispersions and sediments

- Determination of space-resolved mass concentration of dispersed phases

- Determination of concentration changes due to separation phenomena

- Determination of packing density gradient in sediments.

All dispersing agents are possible, being solvent or oil or water. Different measuring cells are available.

LUMiReader X-Ray enables the use of X-radiation for the patented STEP-Technology® (Space and Time resolved measurement of Extinction Profiles). A microfocus X-ray source in combination with a X-ray optics emits parallel, mono-energetic X-rays (I0) onto the entire sample in the measuring cell. The transmitted radiation I is detected by thousands of sensors in a linear arrangement from sample bottom up to the filling height. A microscale resolution is realized. Space and time-resolved transmission profiles are simultaneously detected for for the entire sample height (here 20 mm). The transmission is converted into X-ray attenuation (ln I/I0). The volume concentration can be calculated even for polydisperse samples without knowing the refractive index.

Separation processes, particle migration and particle size changes result in transmission changes. Those are simultaneously characterized space- and time-resolved, up to the display of concentration gradients within a separated phase of high concentration, like sediment or cream layer.

The universal software SEPView® features a Windows-7-based user interface, plug & play, pack & go. The full SOP-concept (creation, capture, data analysis) enables an easy handling. The comprehensive database security and a full audit log are further SEPView features. It complies with CFR21 Part 11.

LUMiReader X-Ray Applications Include e.g. The Qualitative and Quantitative Characterization of

- Flotation, sedimentation, flocculation and consolidation

- Determination of packing densities and concentration gradients in sediments, e.g. for mineral suspensions

- Pigment segregation in paints and cosmetic products, e.g. make-up

- Separation and segregation of oil and minerals in petroleum sand

- Air bubble distribution in solid foams

- Catalyst separation in crude aniline

- Creaming kinetics of silicon oil / water emulsions and packing density of the cream layer

- Flocculation and redispersibility of magnetic dispersions

- Separation of fillers in adhesives

- Segregation in lubricants

- Segregation in and sediment height of solid electrolytes, titanium dioxide/graphite mixtures.

LUMiReader X-Ray is the ideal extension to the established LUM instruments for dispersions. The identical measuring cells can be measured first in LUMiSizer®, LUMiFuge® or LUMiReader PSA and then be analysed in LUMiReader X-Ray. To the advantages of direct and accelerated stability analysis and particle characterization by near-infrared or visible light, the qualitative and quantitative determination of concentration profiles in separated and highly concentrated phases is easily added. LUMiReader X-Ray is sold with type approval according to German X-ray ordinance (RöV).

Specifications

1

2

3

Request information about LUMiReader X-Ray now

Particle analyzers: LUMiReader X-Ray

Separation and Sediment Analysis – All Dispersing Agents Are Possible

Product classification LUMiReader X-Ray

Product categories

Applications

Manufacturers of similar products

Advertisement