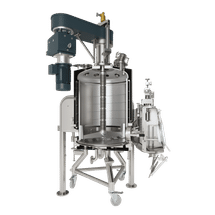

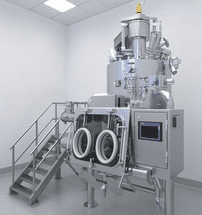

Agitated Nutsche Filter Dryer

Solid-liquid separation and drying All-in-One solution for high value products

Efficient – High yield via design features and precision manufacturing

Versatile –Range of sizes and modular options to address each process

Automation – Control and Software configurations for recipe creation and data monitoring

Create a robust process with PSL ANFD Systems

Everyday our technology is assisting hundreds of pilot and production facilities around the world to reliably manufacture and bring their products to the market faster. PSL Agitated Nutsche Filter Dryers (ANFD) are being used in a wide range of industries such as pharmaceuticals, fine chemicals and precious metals.

Our ANFD Filter Dryer production systems were developed to efficiently wash and isolate solids in the most complex chemical synthesis processes and challenging production environments.

Each of our filter dryers consists of an agitated vessel designed to work under vacuum and under pressure. The vessel can be made of either stainless steel or alloy 22. It is also equipped with a heated jacket and heated agitator for efficient product drying and mixing. Combined Filtration and Drying.

PSL’s Agitated Nutsche Filter Dryers are an all-in-one piece of equipment designed to maximize yield recovery in production activities of high value products. They allow process developers and manufacturers to complete a wide range of processes into one single system.

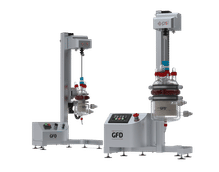

1

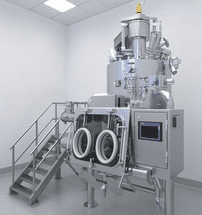

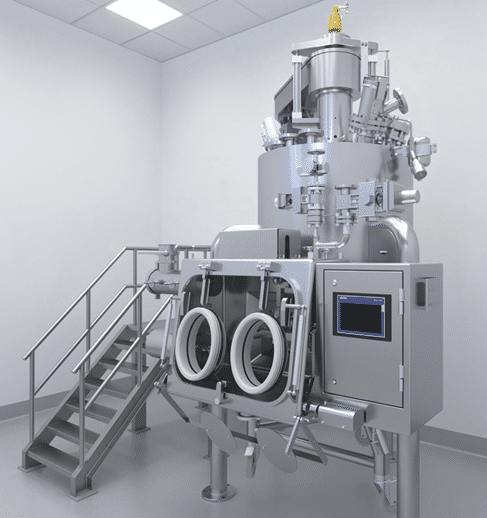

PSL Agitated Nutsche Filter Dryer with discharge Glovebox in cleanroom

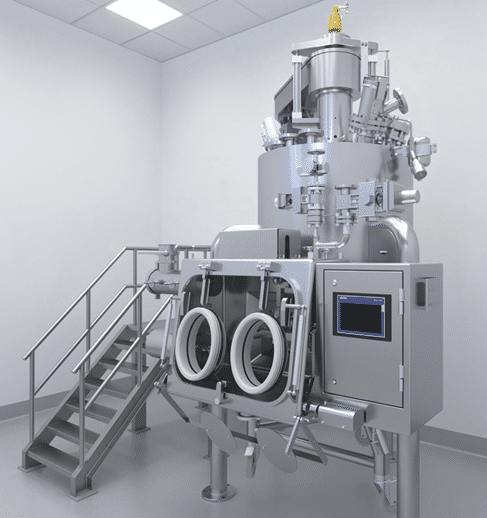

2

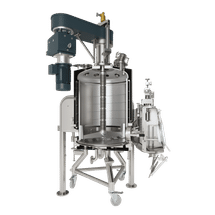

Cut-through view of PSL Agitated Nutsche Filter Dryer

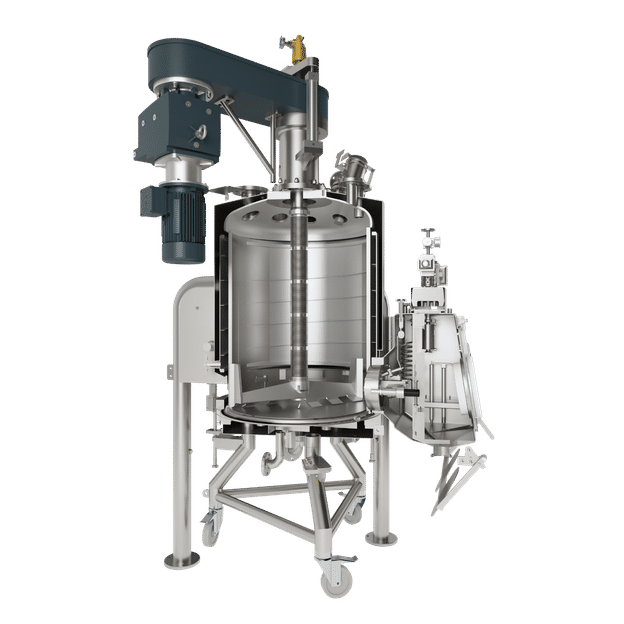

3

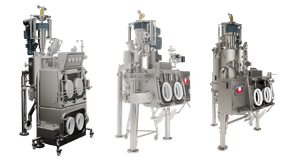

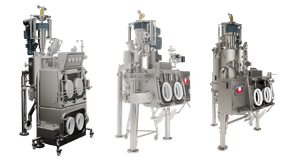

Scale up - Various vessel sizes and various product discharge methods

4

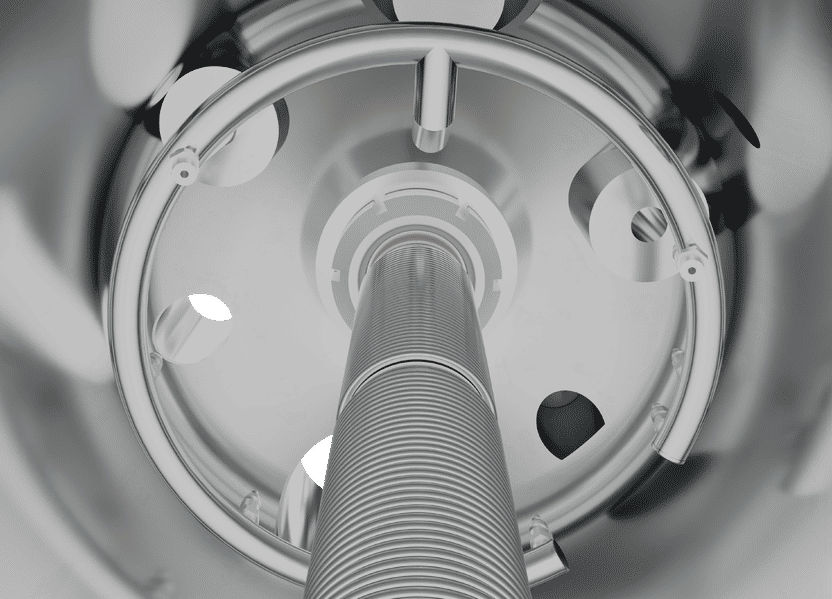

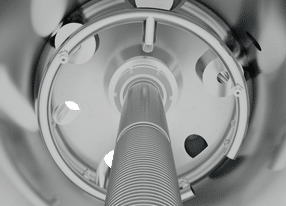

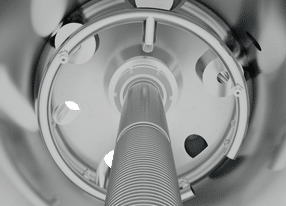

Inside view of vessel with CIP Ring feature and Metallic Bellows

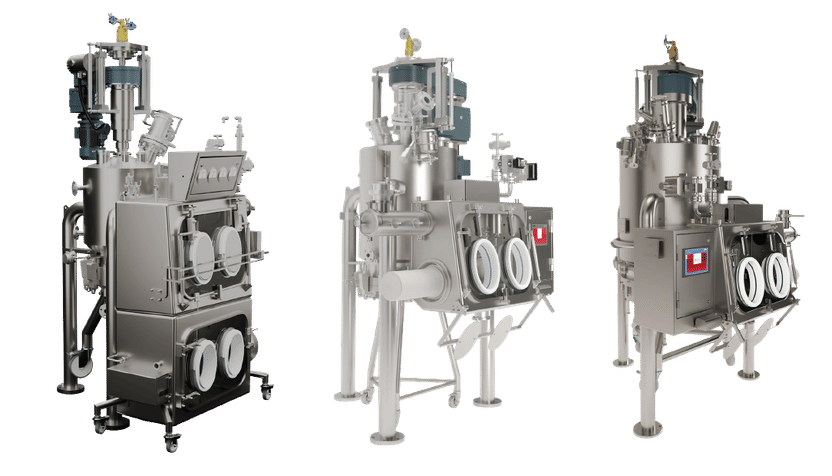

5

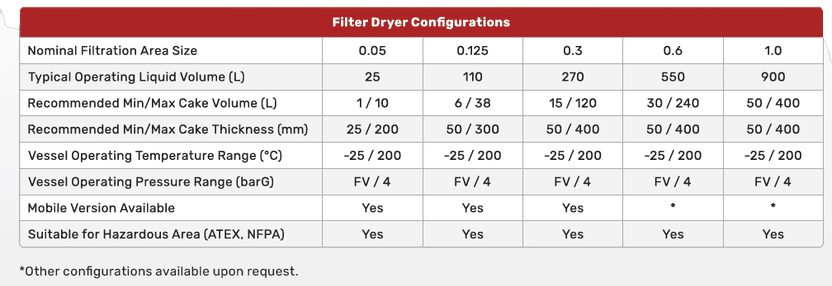

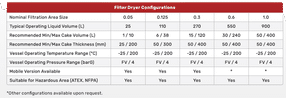

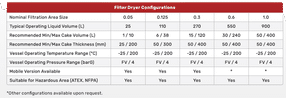

Overview of possible size configuration by PSL

Request information about Agitated Nutsche Filter Dryer now

Nutsche filter dryers: Agitated Nutsche Filter Dryer

Solid-liquid separation and drying All-in-One solution for high value products