SprayMaster inspex

Quality Control for Your Spraying Process Through Digital Spray and Particle Analysis

Cost reduction and quality improvement through online monitoring

Automated real-time measurement integrated in the production process

Digital: Sustainable without paper and film consumption

Reliable, Automated, Digital - The Geometry Measurement of Your Spraying Process in Real Time

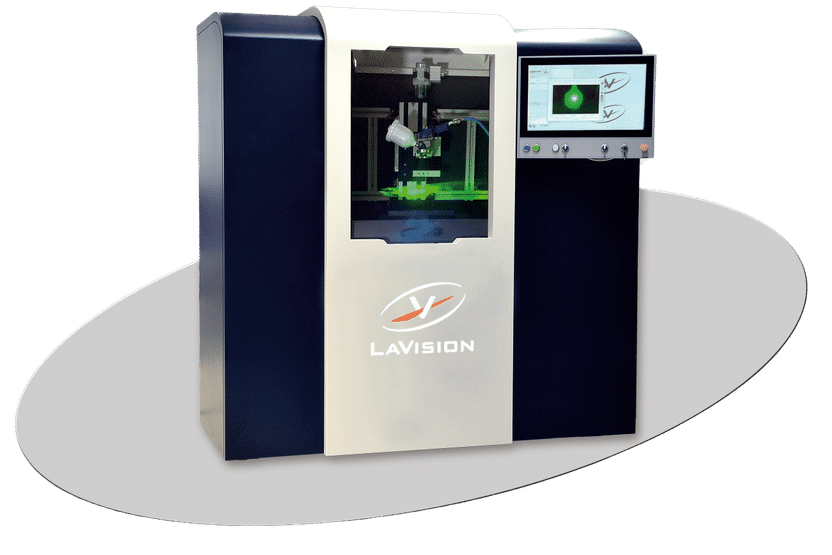

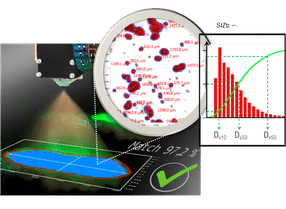

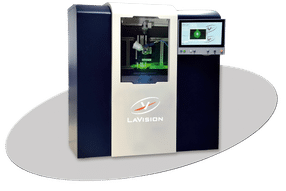

Increase the efficiency of your spraying processes and reduce costs with LaVision's SprayMaster inspex. Integrated into the production process, our system enables the detection of deviations in real-time. The digital imaging measurement technology measures spray formulations of any kind, such as aerosol and powder sprays, for their geometric properties.

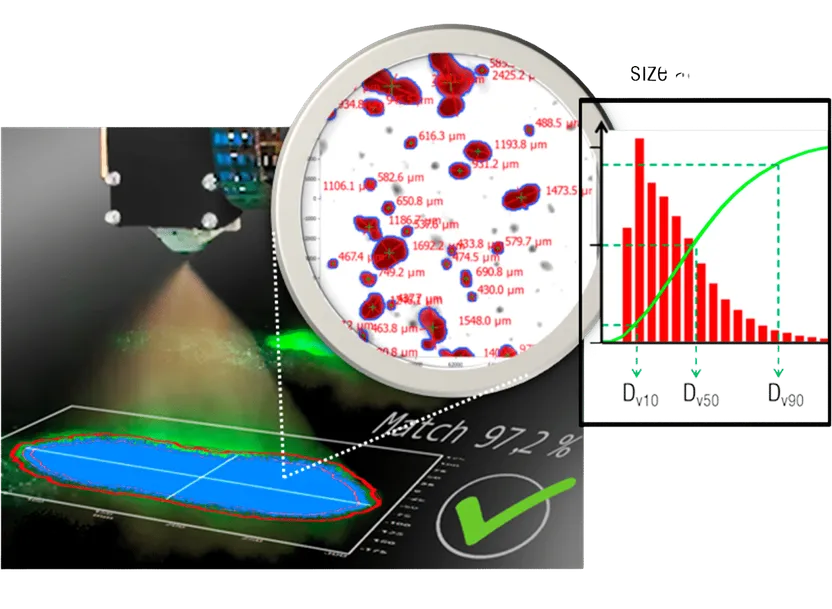

Your spray image is digitally recorded and archived without contact and without the use of paper or foil. Using the integrated measurement process increases inspection frequency and optimizes your process reliability.

Digital processing guarantees repeatable, operator-independent results in fractions of a second. The modular design of SprayMaster inspex increases your benefits in routine spray characterization. Our system family covers all application possibilities, from R&D applications to quality control.

1

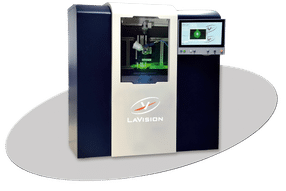

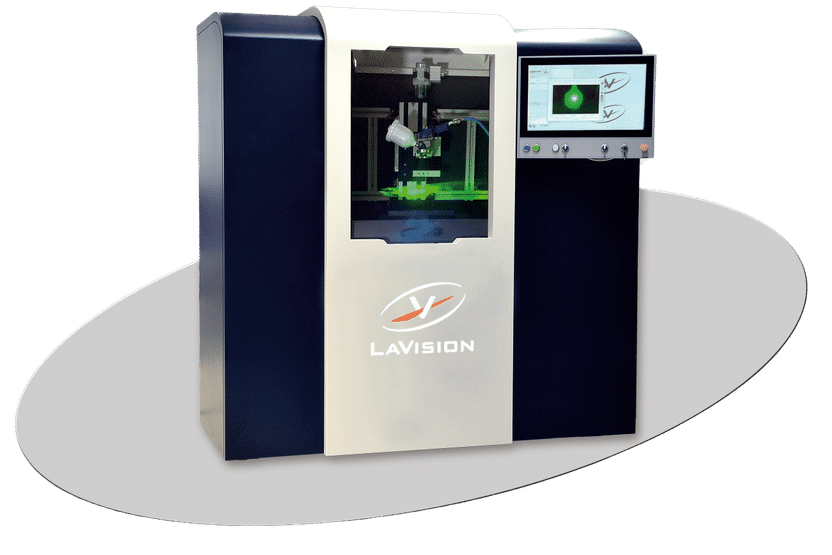

The LaVision SprayMaster inspex laboratory test chamber for operator-based quality testing

2

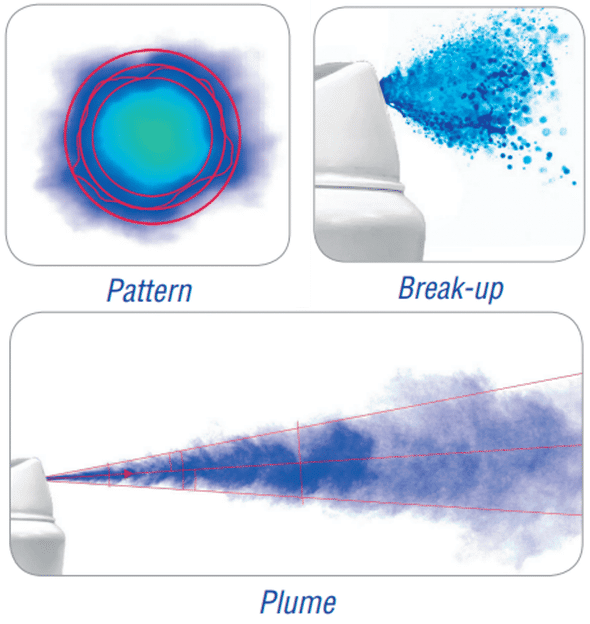

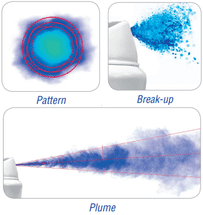

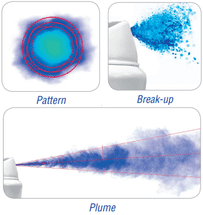

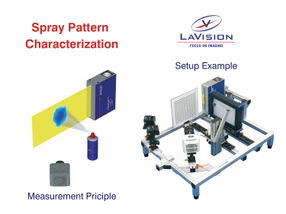

Full visualization and digitalization of spray plume and pattern geometry

3

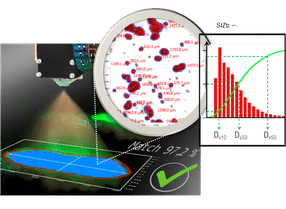

Global spray patternation and local droplet

4

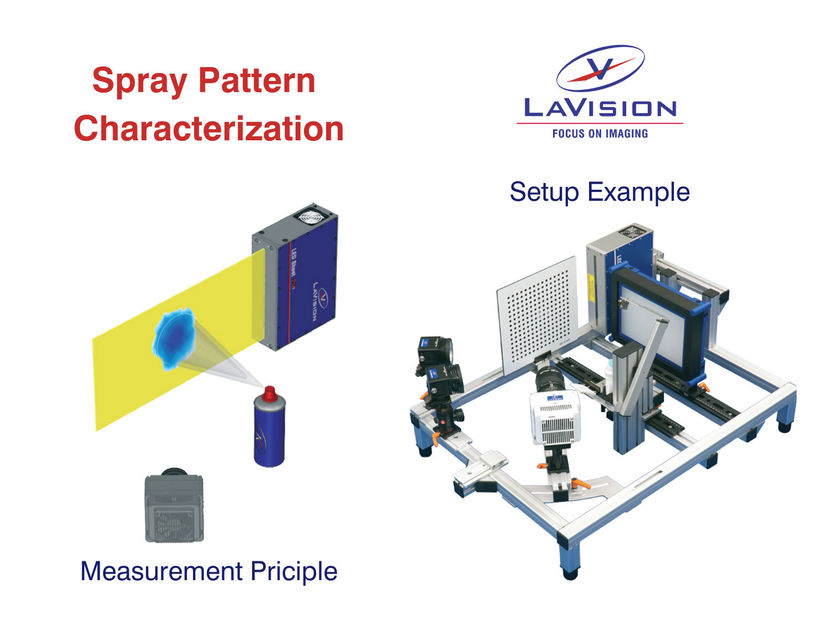

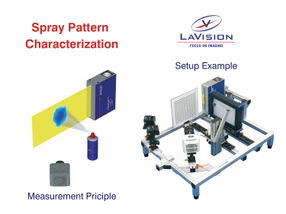

Spray Pattern Characterization

5

Spray Imaging Solutions

Request information about SprayMaster inspex now

Spray analysis systems: SprayMaster inspex

Quality Control for Your Spraying Process Through Digital Spray and Particle Analysis