Laboratory automation systems:

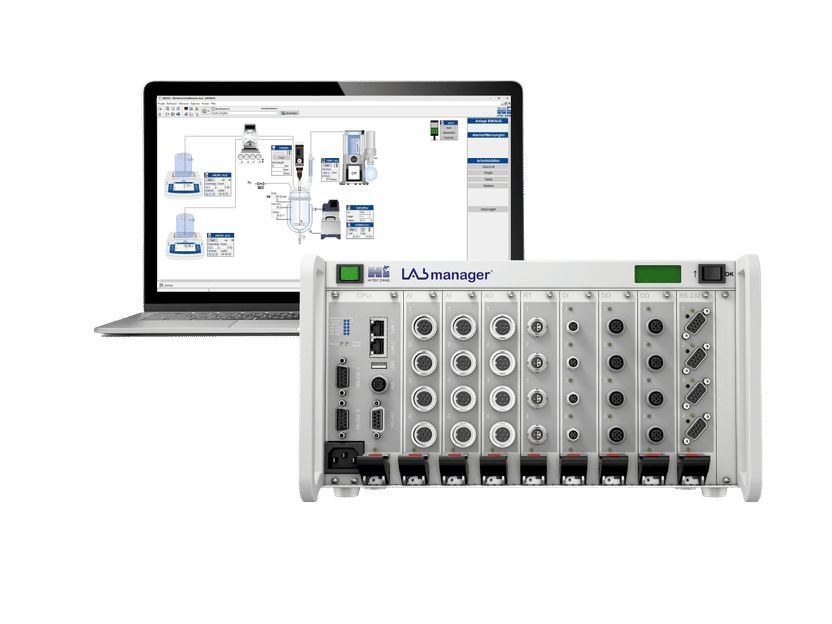

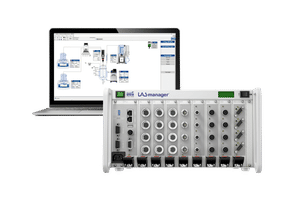

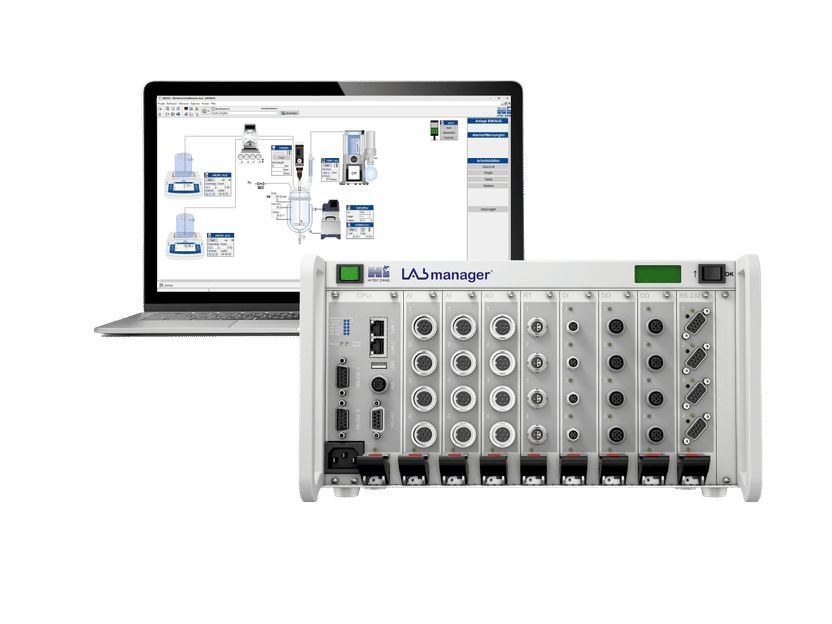

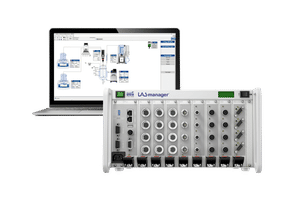

LabVision-System

Process automation for laboratory, pilot plant, miniplants

Complete test documentation

Easily integrate and control laboratory devices

Faster results and improved reproducibility

Automation system for visualizing and automating flow and batch processes

With the LabVision system you can monitor, control and regulate processes in the laboratory, pilot plant and miniplants.

You can easily integrate your laboratory devices such as balances or thermostats via the LabManager. The LabVision software contains predefined project modules for important basic functions such as temperature control, dosing, distillation, pH value or vacuum control. These help you to implement your automation projects quickly. Your process plant is displayed on a screen as a dynamic flow diagram for monitoring and operation, so that you can keep an eye on your process visualization. Our automation system for process development has a modular structure and can be flexibly adapted to any requirement. The spectrum ranges from simple data acquisition or data logger systems to networked process control systems with hundreds of inputs and outputs.

1

One system for your automated laboratorys with pre-defined, functional modules by drag-and-drop

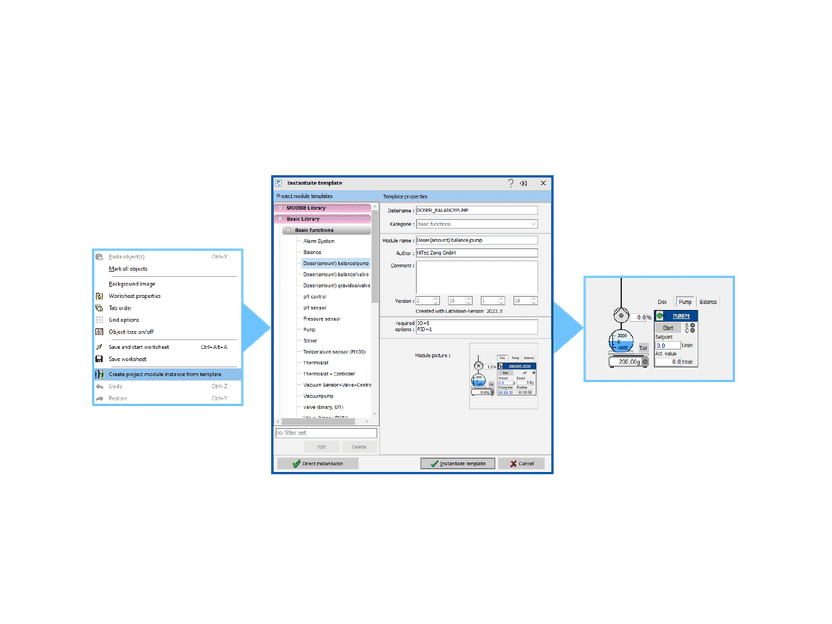

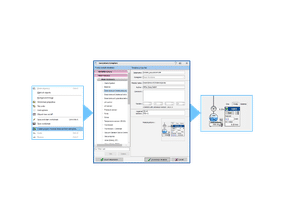

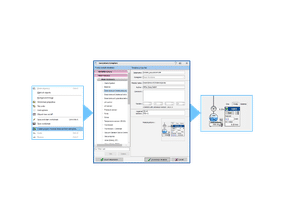

2

Create project modules and integrate them using drag & drop

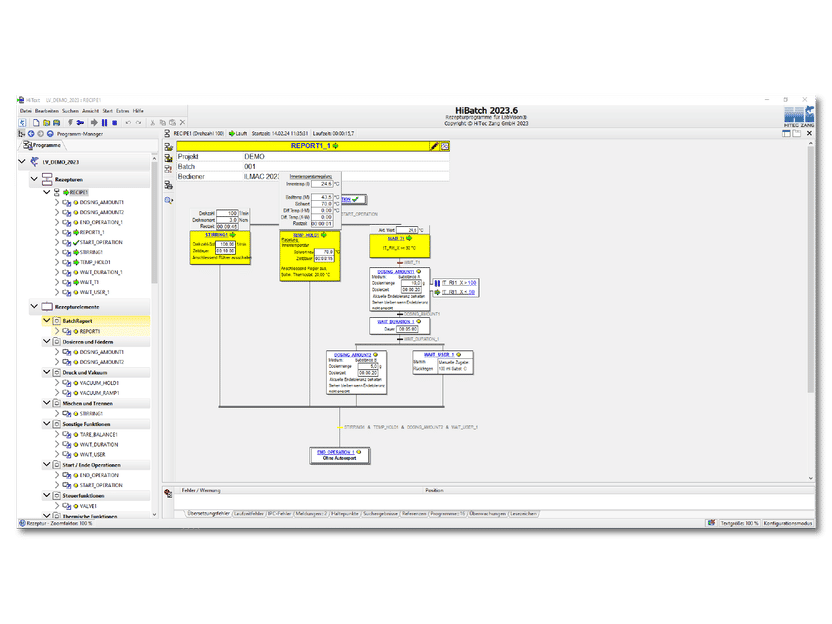

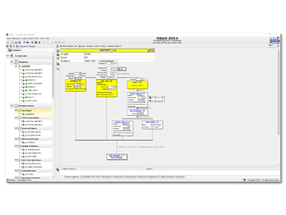

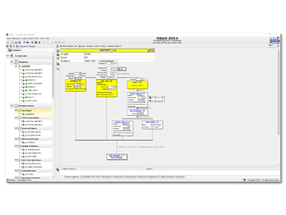

3

Fully automated control and management of graphically controlled recipe processes

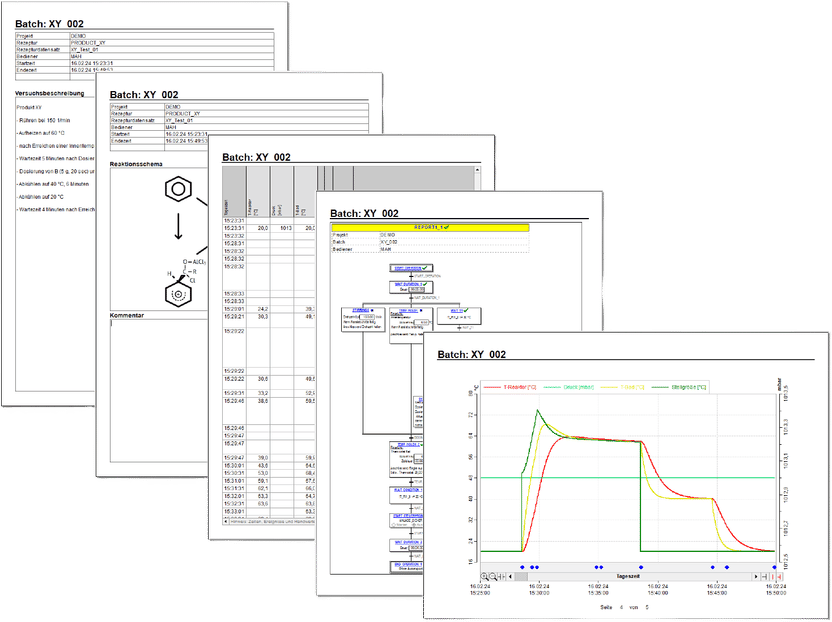

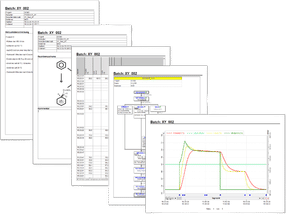

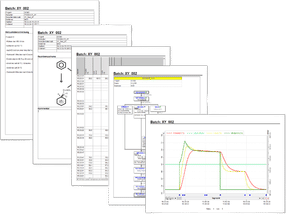

4

Create professional reports

Request information about LabVision-System now

Laboratory automation systems: LabVision-System

Process automation for laboratory, pilot plant, miniplants

Product classification LabVision-System

Product categories

Applications

Manufacturers of similar products

Advertisement

![[Fe]-hydrogenase catalysis visualized using para-hydrogen-enhanced nuclear magnetic resonance spectroscopy - Spectroscopic method provides more precise insights into hydrogen conversion](https://img.chemie.de/Portal/News/675fd46b9b54f_sBuG8s4sS.png?tr=w-712,h-534,cm-extract,x-0,y-16:n-xzoom)