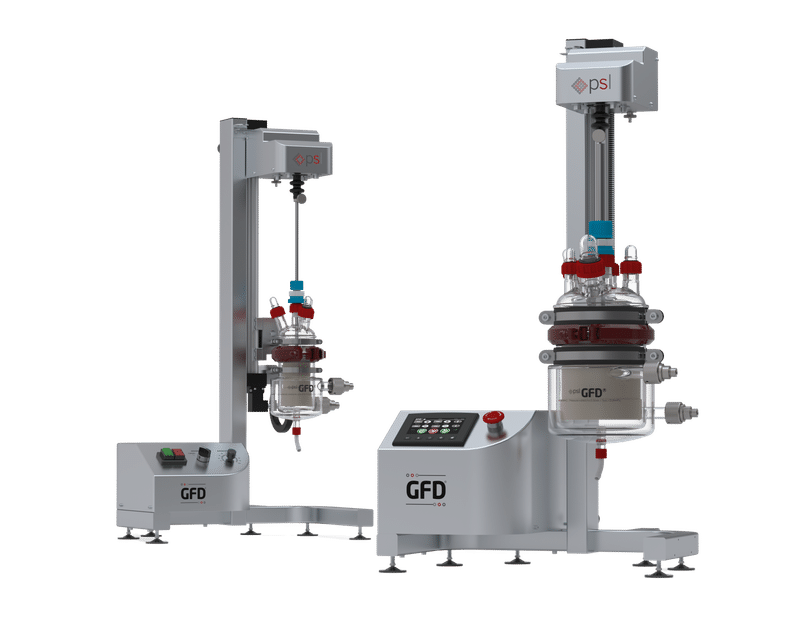

GFD®Lab Agitated Nutsche Filter Dryer

Laboratory Nutsche Filter Dryer for solid-liquid separation and scale-up development

Efficient - Up to 100% product recovery thanks to a unique filtration basket design

Predictable - Programmable recipe sequences for consistent batch reproducibility

Simple - All-in-one unit minimises manual handling and potential product contamination

Modular, all-in-one unit that supersedes traditional Büchner filtration and oven drying methods

Struggling to scale-up your solid-liquid separation process in your lab?

The GFD Lab was developed to overcome well-known production challenges faced by manufacturers when using traditional production methods such as Büchner filtration and oven tray-drying. It is the ideal technology to successfully complete scale-up and scale-down activities and obtain predictive performance results.

It is a miniature version of a production filter-dryer, consisting of an agitated vessel with and integrated heating jacket designed to work under vacuum and under pressure. Vessels are available in either BS 3.3 glass, 316L S/S or Alloy 22. Solid-liquid separation is performed within its unique filtration basket, which can be removed to ease and maximise product collection. Thanks to a 4" HMI touchscreen, production can start at a touch of a button.

Reach out today to see how this world-leading process solution can support your process development activities.

1

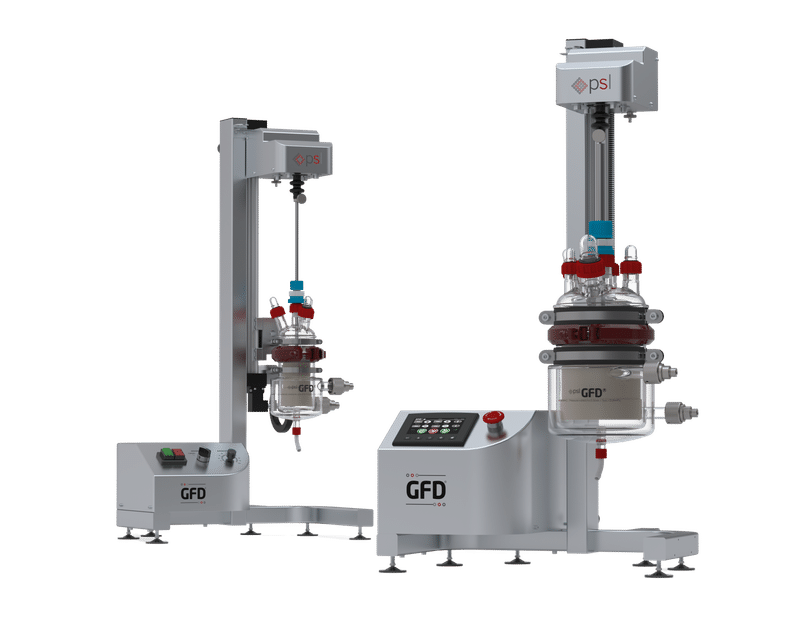

The GFD®Lab and Lab PLUS family of Laboratory Agitated Nutsche Filter Dryers

2

Unique, removable filtration basket design for optimal product recovery

3

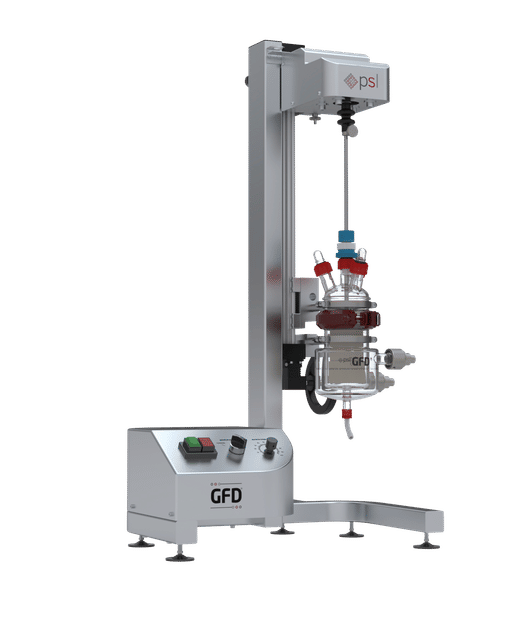

GFD®Lab - Featuring manual operation and 010 Borosilicate 3.3 glass vessel

4

GFD®Lab PLUS - Featuring automated operation and 050 Borosilicate 3.3 glass vessel

5

GFD®Pilot 500 - Ideal for pilot plants and larger batches

Request information about GFD®Lab Agitated Nutsche Filter Dryer now

Nutsche filter dryers: GFD®Lab Agitated Nutsche Filter Dryer

Laboratory Nutsche Filter Dryer for solid-liquid separation and scale-up development