Nanofarming technology harvest biofuel oils without harming algae

Ames Laboratory and Catilin seek to commercialize new algal oil extraction process

algae is widely touted as the next best source for fueling the world's energy needs. But one of the greatest challenges in creating biofuels from algae is that when you extract the oil from the algae, it kills the organisms, dramatically raising production costs. Now researchers at the U.S. Department of Energy's Ames Laboratory and Iowa State University have developed groundbreaking "nanofarming" technology that safely harvests oil from the algae so the pond-based "crop" can keep on producing.

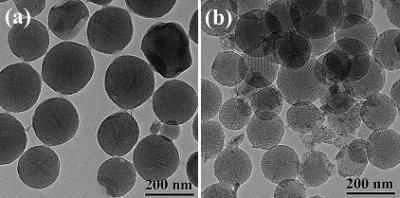

This micrograph shows the sponge-like mesoporous nanoparticles developed by researchers at Ames Laboratory to harvest biofuel oils from algae without harming the organisms.

Commercialization of this new technology is at the center of a Cooperative Research and Development Agreement between the Ames Laboratory and Catilin, a nano-technology-based company that specializes in biofuel production. The agreement targets development of this novel approach to reduce the cost and energy consumption of the industrial processing of non- food source biofuel feedstock. The three-year project is being funded with $885,000 from DOE's Office of Energy Efficiency and Renewable Energy, and $216,000 from Catilin and $16,000 from Iowa State University in matching funds.

The so-called "nanofarming" technology uses sponge-like mesoporous nanoparticles to extract oil from the algae. The process doesn't harm the algae like other methods being developed, which helps reduce both production costs and the production cycle. Once the algal oil is extracted, a separate and proven solid catalyst from Catilin will be used to produce ASTM (American Society for Testing and Materials) and EN certified biodiesel.

The potential of algae for fuel is tremendous as up to 10,000 gallons of oil may be produced on a single acre of land. The DOE estimates that if algae fuel replaced all the petroleum fuel in the United States, it would require only 15,000 square miles, which is a few thousand square miles larger than Maryland. This is less than one-seventh the area devoted to corn production in the United States in 2000.

The driving force behind this combination of nanotechnology and biofuels is Ames Laboratory Chemical and Biological Sciences Program Director Victor Lin. Since 2000, Lin, who is also a chemistry professor at Iowa State University, has been leading research on using nanotechnology to dramatically change the production process of biodiesel. This successful technology led Lin to found Catilin one and a half years ago.

"By combining nanotechnology, chemistry and catalysis, we have been able to find solutions that have not been considered to date," Lin said. "Ames Laboratory and Iowa State University offer valuable research capabilities and resources that will play a key role in this exciting collaboration with Catilin."

According to Marek Pruski, Ames Laboratory senior physicist and co- investigator on the project, phase one and two of the project will cover the culturing and selection of microalgae as well as the development of the specific nanoparticle-based extraction and catalyst technologies for the removal of algal oil and the production of biodiesel, respectively. Phase three will focus on scale-up of the catalyst and pilot plant testing on conversion to biodiesel.

"When we ultimately put together this exceptional extraction technology with Catilin's existing solid biodiesel catalyst, we will dramatically increase the reality of renewable energy," said Catilin's CEO, Larry Lenhart. "Given the Obama administration's objectives, the timing is perfect."

Most read news

Topics

Organizations

Other news from the department science

These products might interest you

NANOPHOX CS by Sympatec

Particle size analysis in the nano range: Analyzing high concentrations with ease

Reliable results without time-consuming sample preparation

Eclipse by Wyatt Technology

FFF-MALS system for separation and characterization of macromolecules and nanoparticles

The latest and most innovative FFF system designed for highest usability, robustness and data quality

DynaPro Plate Reader III by Wyatt Technology

Screening of biopharmaceuticals and proteins with high-throughput dynamic light scattering (DLS)

Efficiently characterize your sample quality and stability from lead discovery to quality control

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.