BASF temporarily idles steam cracker in Ludwigshafen

Order levels remain generally low

BASF will idle the smaller of its two steam crackers at its site in Ludwigshafen due to continuing weak demand. The temporary shutdown of the cracker, which has an annual capacity of 220,000 metric tons of ethylene, is planned for the middle of April and will last at least three months. Overall, a total of five production lines are currently idled at the Ludwigshafen Verbund site, and an additional 60 production lines are operating at very low capacity utilization rates. BASF has reduced its production capacities worldwide by more than 25 percent.

“Demand from key internal customers in our Production Verbund has unfortunately remained low over the past weeks,” said Dr. Albert Heuser, President of BASF’s Petrochemicals division. “We do not expect any improvement in the foreseeable future, for example for production lines that serve the automotive industry. We are therefore tailoring production to reflect demand and to reduce costs.”

The employees from the steam cracker can be transferred to other production plants at the site for the time being. Since first implementing capacity reductions in November, BASF has been using flexible working time arrangements wherever possible, which also includes transferring employees between plants with varying capacity utilization rates.

“We are using the strategic advantages offered by the size and flexibility of our integrated Verbund sites,” explained Dr. Bernhard Nick, manager of the Ludwigshafen site. “At the moment more than 500 employees are already working temporarily in other plants. This is the main reason why we have so far been able to avoid short-time working here in Ludwigshafen. However, this possibility will soon be exhausted if the situation does not improve.” In January, the company’s management reached a provisional agreement with employee representatives that will allow the rapid introduction of short-time working in Ludwigshafen if necessary.

The steam cracker uses steam to “crack” naphtha at a temperature of about 850°C. Among other products, this produces ethylene and propylene – important basic chemicals used to product many BASF products such as plastics or raw materials for paint.

Other news from the department manufacturing

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

Last viewed contents

Actinometer

Tiger's_eye

Cytarabine

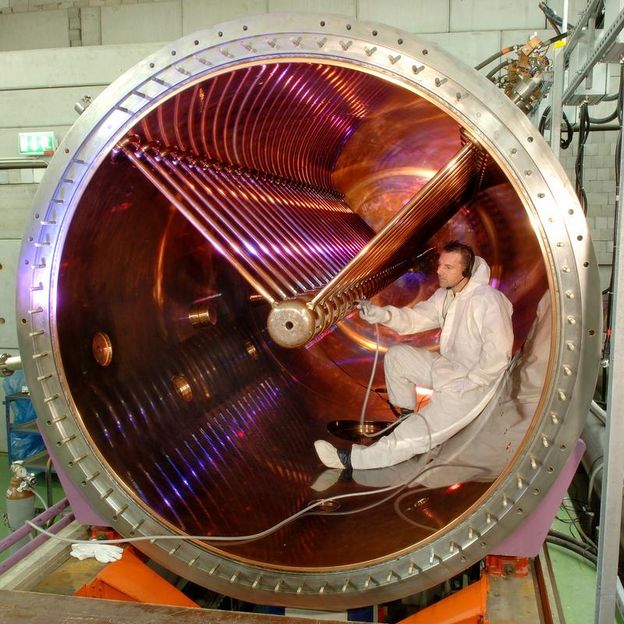

Detecting fake wine vintages: It's an (atomic) blast

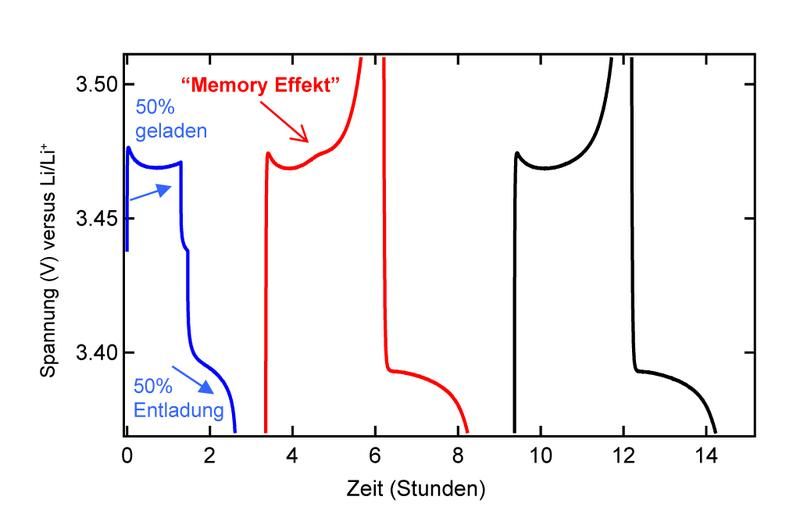

Memory effect now also found in lithium-ion batteries

Sigmatropic_reaction

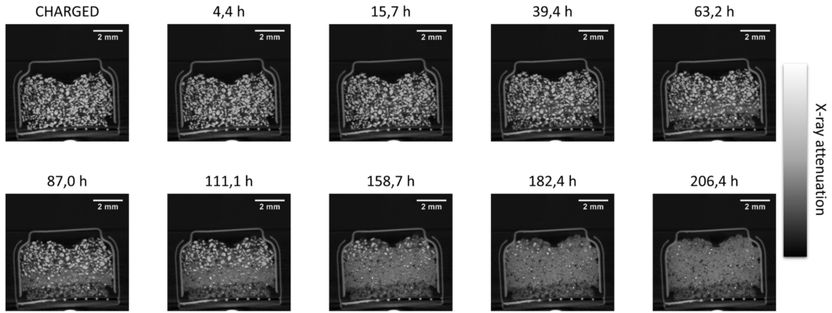

A fast 4D look into materials and substances - A project is developing an AI-based software framework that can process terabyte-sized 4D tomography data on a desktop PC

Element 112 shall be named "copernicium" - Proposed name honors astronomer Nicolaus Copernicus

How seashells get their strength

CSIC presents its prototype vanadium battery for large-scale electrical energy storage - 10 kW redox flow demonstrator paves the way for a 50 kW flow battery

Nobel Prize in Chemistry for 2009 for studies of the structure and function of the ribosome - The ribosome translates the DNA code into life