Carbon Nanotubes: Endless Opportunities

carbon nanotubes (CNTs) are the most popular and recognizable elements of present nanotechnology. Scientists and researchers now are discovering that carbon nanotubes could be more affordable and useful to many industrial areas, including flame retardant materials market. The global flame retardant chemicals market is valued at just under $3 billion, with demand for non-flammable products ever growing. The compound annual growth rate of this market is estimated at 4% to 5% for the total market up to 2015. There will be stable demand in established markets such as North America and Europe. As of 2006, the North American market was valued at $780 million, and the European market was valued at $762 million. Based on their analysis, Frost & Sullivan believe there are growing market opportunities for carbon nanotubes application as a flame retardant material.

“Now, CNTs are perceived as promising additives even in the flame retardant solutions. Based on our market recognition we are assuming that phosphorous-based flame retardants will be the best market for carbon nanotubes as a flame suppressing agent to pursue in the future. Decreasing price of this additive will be accompanied by improvement in carbon nanotubes “know how” with developers and end users awareness about their beneficial features,” states Krzysztof Grzybowski, Frost & Sullivan analyst for Technical Insights group.

Of the three types of nanotubes (single, double and multi-walled particles), single walled particles are judged by scientists to offer the greatest potential. However, Multi-Walled Carbon Nanotubes (MWCNTs) are the most reasonable ones for commercialization as a composite additive or coating element. They can be produced on a high scale at a relatively low price.

Originally costing about $1000 per gram (for single walled nanotubes), MWCNTs can now be mass produced for only $100/kg depending on the shipping. This price is expected to decrease to about $10-20/kg in a few years. New technological developments in nanotubes fabrication will increase its production capabilities. Bayer Materials has announced plans of increasing production capacity of MWCNTs from 60 tones per year in 2007 to 3000 tones per year by the end of 2012. With plans like this in place, commercial industries will no longer find cost a deterrent.

The carbon nanotubes are now being incorporated in various solutions as an agent providing non flammable feature to various products and coating layers. As a flame retardant additive, MWCNTs prove to make stronger and more fatigue resistant material. It also tests beneficial for materials’ electrical properties.

The need for fire resistant material is rising. Current regulations are forcing producers from the household sector, electronics, building and construction, transportation, and many others to meet increasingly stringent standards of fire safety. Commercialized products that benefit from flame retardants include plastic enclosures for consumer electronics, printed circuit boards, wire and cable, electrical connectors, foam insulation, foam seating in furniture, automobiles, and textiles.

CNTs are more sought after than its cheaper brother, carbon nanofibers, because CNT particles provide material non-flammability with relatively small concentration compared to the other fillers. This in effect makes CNTs less visible and less noticeable by the end user in the resultant material. CNTs increase nonflammability, while enhancing material strength or providing an electrostatic discharge effect.

The only major hoop left to jump through is ensuring proper homogenous dispersion of CNTs for maximum benefit. Experiments proved that material failure as a flame retardant is attributed to poor dispersion. However, this problem can be easily avoided through current producers’ technologies. To make sure of the quality of their product, current CNTs producers are often selling them in the convenient form of master batches that help end users to fully take advantage of CNTs’ beneficial features.

Most read news

Topics

Organizations

Other news from the department business & finance

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

Most read news

More news from our other portals

Last viewed contents

Your Monitor as an Analytical Tool - Detection of amines, CO, and NOx by computer monitor and web camera

Space: Air Liquide and Astrium create EuroCryospace

Abgenix And Sangstat Receive Orphan Drug Designation For Abx-Cbl For Treatment Of Acute Graft Versus Host Disease

AkzoNobel Science Award honors two Swedish professors

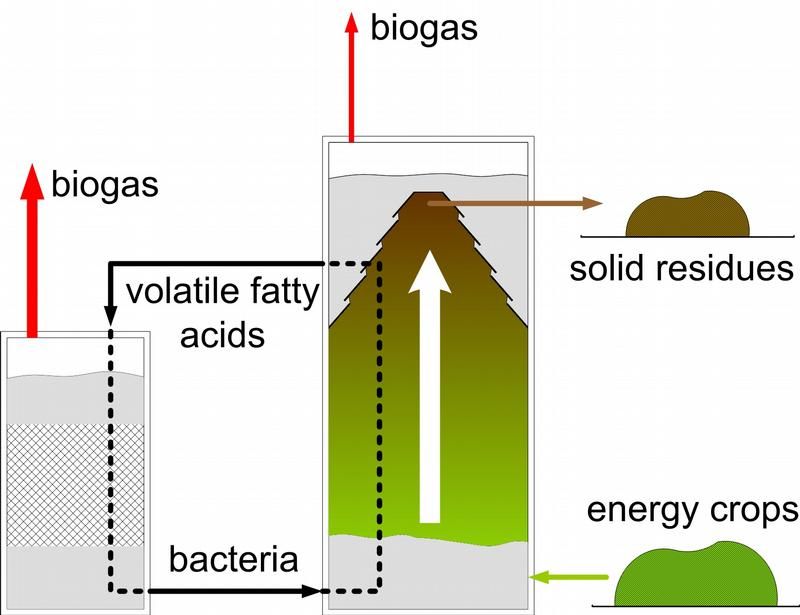

Neither shaken nor stirred: A novel high rate system for biogas production from energy crops

AkzoNobel to outline new strategy - Plan for enhanced value creation