Borealis takes high-speed route to new product development

New lab reactors in Linz already yielding better-than-expected results

All polypropylene reactors in a new laboratory at the Borealis Innovation headquarters in Linz, Austria, are now up and running and yielding results well beyond original expectations, according ot the company. The reactors will form an important part of the company's strategy to accelerate product development.

The bench-scale reactors are equipped with a plant process control system, and they accurately mimic full-sized reactors using Borealis' proprietary Borstar technology. They will therefore enable Borealis to telescope time for product evaluations and bring new products to market faster and more cost-effectively.

“The successful start-up extends our innovation capability enormously”, says Dr. Alexander Krajete, Borealis polymerization expert and project manager for the new investment. “Rather than limiting ourselves to a few test runs on a pilot plant, we can now carry out literally hundreds of tests right here in the laboratory, in the full knowledge that we can scale up to full-sized production and get similar results.”

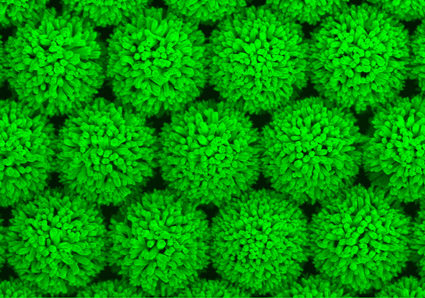

A key factor behind the new success of the project is the gas purification system installed on the reactors. “It filters out every last component, which has a significant effect on catalytic activity,” he says. “We can now work in the lab with the most sensitive metallocene catalysts and are seeing fantastic catalyst activity and process consistency, much better than we anticipated.” The reactors produce bright white polymer particles with a highly uniform shape and without agglomerates or dust.

Organizations

Other news from the department science

These products might interest you

JUCHHEIM LabClave: Druckreaktoren by JUCHHEIM Laborgeräte

Customized stainless steel reactors - configured for your needs

Perfect for extraction, digestion, hydrolysis, hydrogenation or synthesis

BUCHI MINICLAVE by C3 Prozess- und Analysentechnik

Flexible small reactor systems - acid resistance, visual control and individual customization options for a wide range of applications!

BUCHI MINIPILOT by C3 Prozess- und Analysentechnik

Discover the versatile glass reactors - the perfect solution for your chemical processes

BUCHI NOVOCLAVE by C3 Prozess- und Analysentechnik

Extreme performance for demanding laboratory applications - Discover the new high-pressure autoclave!

BUCHI POLYCLAVE by C3 Prozess- und Analysentechnik

Flexible and safe working with the most versatile pressure reactor system on the market

HiClave by JUCHHEIM Laborgeräte

Modular high-pressure reactors - flexible to configure

Ideal for hydrogenation, oxidation, carbonylation, polymerization

Xelsius Reaction Work Station by nevoLAB

10 reactions – individually controlled in just one instrument

Ideal for parallelsynthesis, reaction optimization, solvent screening, crystallisation & DoE studies

FlowSyn and FlowSyn Maxi by Uniqsis

Continuous Flow Chemistry Systems for reaction optimisation and scale up

Perform reactions up to 300°C and 100 bar from 0.1 - 100 ml /minute

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.