New waterproofing process without mineral salts

Waterproof leather with good breathing properties and wear comfort

Advertisement

Leverkusen – The production of high-quality waterproof leather is a challenge to both leather chemists and applications technologists – especially if long-lasting waterproofness is required and no mineral salts are to be used for fixation. Now research scientists from Bayer AG in Leverkusen have succeeded in developing a waterproofing system which uses no fixing agents containing mineral salts and combines good wear comfort with high water vapor permeability and low water absorption. This system, which is extremely easy to use, preserves the breathability of natural leather, while at the same time giving excellent, long-lasting waterproofness under dynamic stress. Since no chrome salts are used as fixing agents, the quality of the surface and the color intensity of the treated leathers are noticeably improved.

The new, open, chrome-free waterproofing system leads to waterproof leather which is capable of withstanding dynamic stress, yet still has good breathing properties and can be subjected to over 50,000 flexes in the Maeser test or eight hours in the Bally penetrometer without allowing water to penetrate. It is also suitable for producing very soft leathers. The system is simple to meter, ecologically sound and satisfies the highest demands with regard to the quality of the surface and the handle and dyeing properties of the treated leather. It is currently marketed under the names Xeroderm® P-AF and Xeroderm® S-AF.

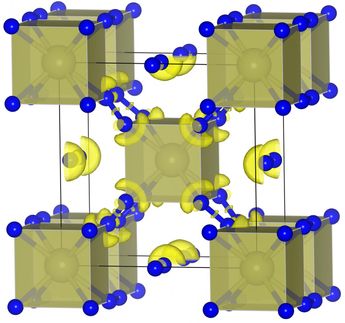

The new, two-component waterproofing system consists of a special polyacrylate, Xeroderm® P-AF, which reduces the water absorption while at the same time preserving the full water vapor permeability of the leather, and a silicone, Xeroderm® S-AF, which is specially tailored to leather chemistry and ensures exceptionally good waterproofness of the leather under dynamic stress. No additional operation is needed when waterproofing with these Bayer products. The process can be incorporated into the normal wet finishing operation without any problems and without adding to the time required. The waterproofing agents are simply added in place of the fatliquoring system for softening. They are then fixed with formic acid to give a long-lasting effect which cannot be washed out. Absolutely no mineral salts such as chrome, aluminum or zirconium salts are needed for fixation.

The new products can also be used in the production of very pale colored or brilliantly dyed waterproof leathers, and so there is nothing to stop ambitious fashion designers from using these colors for outdoor clothing as well.

Most read news

Other news from the department research and development

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.