Dow Corning Achieves Quality Milestones In Silicon Carbide Semiconductor Manufacturing

Improvements move silicon carbide device technology closer to high volume manufacturing

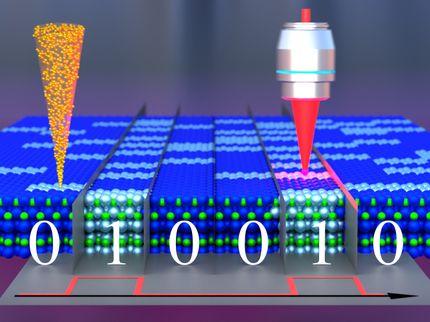

Improvements in manufacturing technology have dramatically reduced defects in silicon carbide (SiC) semiconductor wafers and epitaxy, which could lead to greater energy efficiency, performance and smaller size of a variety of electronic products, researchers at Dow Corning have announced.

Over the last two years, Dow Corning has steadily reduced micropipes — a key defect that has been a major challenge for the industry — from an average of well over 100 per cm² to less than 10 per cm² and is on track to be well under 5 per cm² by year end, said Jim Helwick, Gobal Business Director, Dow Corning Compound Semiconductor Solutions. At the same time, X-ray measurements of crystal quality show a better than five-fold improvement and average epitaxy defects were reduced 900 percent in 18 months.

“These improvements are critical to drive efforts to move silicon carbide device technology closer to high volume manufacturing,” Helwick said. “The rapid technical advances in compound semiconductors combined with growing market interest in improved energy efficiency and performance put Dow Corning in a good position to support our customers with a valuable new semiconductor technology.”

Other news from the department research and development

Get the chemical industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.